Connect supply cable : the yellow-green wire of cable

must be connected to an efficient earth point of the

system, the remaining wires should be connected to the

feed line through an isolation switch placed, if possible,

close to the working area so as to switch the unit off

quickly if necessary.

6

The magnetothermic switch capacity or of fuses in series

with switch should be equal or above the current

I

1

absorbed is known

by reading the

technical specifications

on the

unit i.e. feed voltage U

1

available.

Any extensions should have adequate sections for current

absorbed

I

1

.

2.3 OUTPUT CONNECTIONS

2.3.1 Connecting the electrode holder

•

The electrode holder must be connected to the machine

in compliance with the polarity indicated on the box of

electrodes that you are going to use.

•

When you connect the electrode holder cable and the

hearth cable, make sure that the power cable terminals

are well tightened.

•

The jaws of the electrode holder must be kept tightened

and the surfaces must be kept in good condition to ensure

good contact with the electrode rod.

•

Defective jaws will allow the electrodes to move which

will make welding difficult.

•

The connection between the electrode holder cable and

the electrode holder must be well tightened.

•

Use well insulated electrode holders.

•

Never touch the electrode holders of two different

welding machines at the same time.

•

Always avoid contact between parts of the body and the

electrode holder and/or the electrode.

2.3.2 Connecting the Earth Clamp

•

Make sure that the earth clamp makes good contact

with the workpiece.

•

Check that the earth cable is tightly fitted to earth clamp;

periodically check to make sure that this connection

remains well tightened.

A poorly tightened connection can cause current drops

during welding and also cause overheating of the earth

clamp and cable which can create the danger of burns.

•

The weld circuit must not be purposefully placed in

direct or indirect contact with the protection lead if not in

the workpiece.

•

If the workpiece is intentionally connected to the system

earth by means of a protection lead, the connection has to

be as direct as possible and done with a lead that has a

cross section at least equal to that of the welding current

return cable.

A second earth clamp, placed in the immediate vicinity,

can also be used.

2.3.3 Choosing the right welding cables

We recommend using the shortest possible welding

cables type H01 N2-D or H01 N2-E, in compliance with

CENELEC HD22.6 S1.

Too much resistance in the welding cables can reduce the

output available for the welding.

The performance of any arc welding machine depends,

generally, on the condition of the cables and the cable

connections.

CROSS SECTIONS OF WELDING CABLES IN mm

2

WELDING

CURRENT IN

AMPERE

DISTANCE IN METRES FROM THE

MACHINE

15

20 30 40 45

50

60

100

35

35 35 50 50

50

50

150

35

35 50 50 70

70

90

200

35

50 50 70 70

95

100

250

35

50 70 70 95

100 150

300

50

70 70 95 100 150 150

350

50

70 95 100

150 150 200

400

50

95 95 150

150 200 210

NOTE: The cross sections listed in the table are those for

each single conductor (electrode holder or ground clamp).

The cross sections listed in the table are those for each

single conductor (electrode holder or group clamp).

The cross sections of the cables can be obtained by

connecting in parallel 2 or 3 conductors having the same

cross section. For example :

150mm

2

=three 50mm

2

cables linked together in parallel.

200mm

2

=2x95 mm

2

cables or 3x70 mm

2

cables linked

together in parallel.

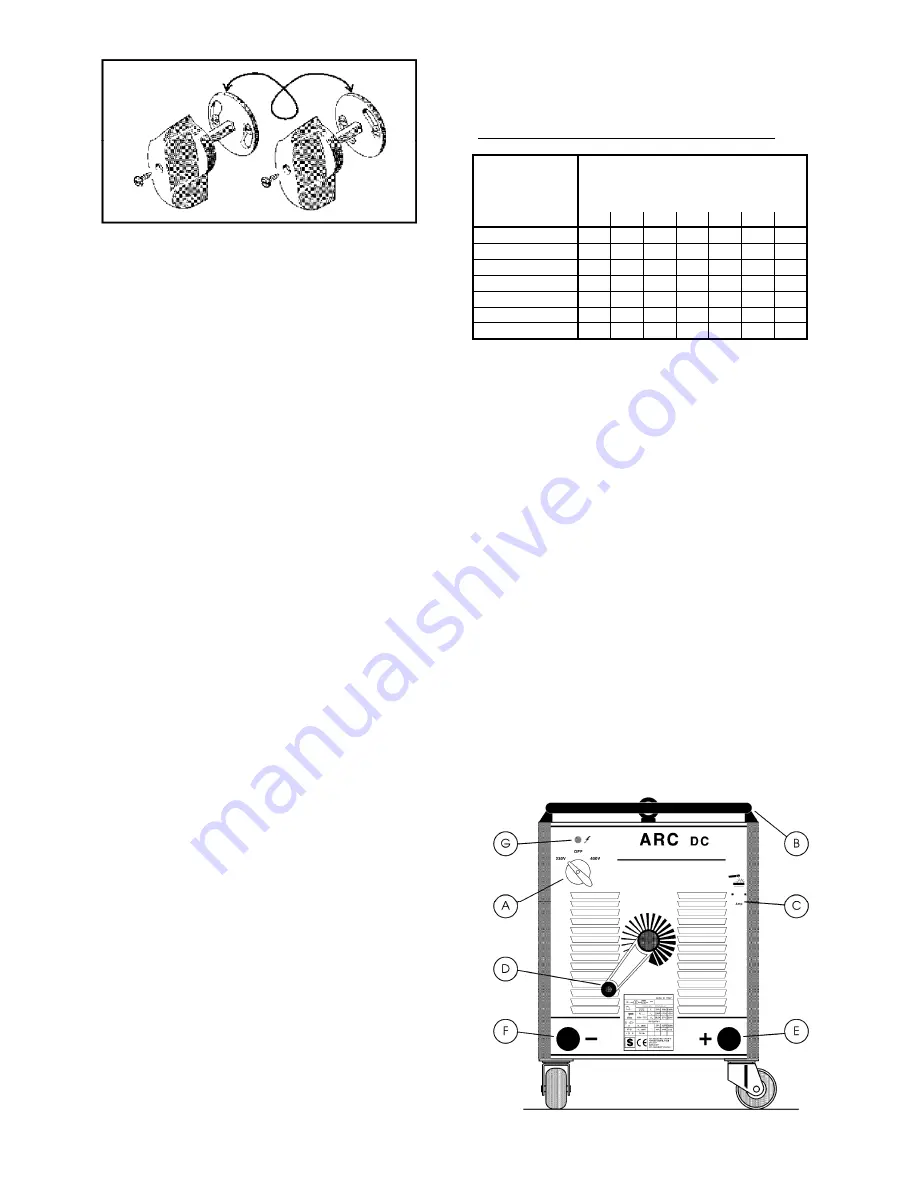

2.3.4 Connecting two welding machines in parallel

Two welding machines can be connected in parallel so that

one obtains on output current greater than the output

current of each single machine.

It is important that the positive pole of one machine is

connected to the positive pole of the other machine and

likewise that the negative pole of one machine is connected

to the negative pole of the other machine.

When making this connections it is important to abide by the

cross sections shown in the table.

After having connected two machines in parallel, set the

output current of each machine to the halfway point so that

each machine will produce half of its maximum output

current.

This is recommended in order to balance the heath

produced by each machine, thus allowing the operator to

make the best use of duty cycles of both machines.

3 PANELS DESCRIPTION

Содержание MMA 793

Страница 21: ...Artt Items 793 794 795 798 799 21...

Страница 23: ...Art 796 797 23...

Страница 25: ......

Страница 26: ...Cod 381656 10 2009...