9

ENGLISH

performance

Malfunctioning

check valve

Check or change the

check valve

Incorrect stop

frequency

Check and set

proper value

STUCK PUMP

Prolonged

inactivity resulting

in scaling,

oxidation and

limescale

formation

Careful pump

cleaning and

maintenance

Presence of

foreign objects

Remove the foraign

objects

Blocked or

broken bearings

Change bearings

NOISY PUMP

AND/OR

EXCESSIVE

VIBRATION

Worn bearings

Change bearings

Worn or broken

impellers

Change impellers

Presence of air

Check proper pump

priming

Undersized or

incorrectly

secured pipes

Correct sizing of

suction and

discharge pipes and

secure pipes

Wrong duty point

setting

Set the proper duty

point

PUMP OPERATES

BUT DOESN'T

DELIVER

ENOUGH

PERFORMANCE

(FLOW RATE

AND/OR

PRESSURE)

Pump undersized

for system

requirements

Check pump

performance if it

complies with

system

requirements

Pump not

properly primed

and doesn't

achieve required

performance

Properly prime the

pump and check for

air infiltration and/or

leaks

Blocked or

obstructed foot

valve

Remove obstruction or

unblock foot valve. If

necessary, replace

foot valve

Wrong rotation

sense (low

performances)

Check the rotation

sense and phases

connection

Improperly sized

pipes (excessive

pressure losses)

Sizing the system

piping properly

Excessive height

difference (if

overhead

installation)

Decrease suction

height

Excessive liquid

viscosity (if

different than

water)

Pump model not

suitable for service

or incorrect pressure

drop calculation /

pump selection

WATER

LEAKAGE

Excessive wear

or mechanical

seal failure

Change mechanical

seal

Excessive wear

or breakage of

gaskets

Change gaskets

Pipes not

properly tightened

at joints

Check correct

tightening of joints

PUMP RUNS IN

REVERSE WHEN

STOPPED AND

STARTS AGAIN

IMMEDIATELY

Unit foot valves or

non-return valves

not functioning

properly

Check correct

functioning of non-

return valves and

replace if necessary

TOO

FREQUENT

PUMP

RESTARTS

Incorrect setting

of set pressure

and restart

pressure

parameters

Check and set

proper parameters

(see the control

panel user manual)

Incorrect setting

and adjustment of

the pressure

switches

Correct adjustment

of pressure switches

No or incorrect

preloading/sizing

of pressure

vessel

Install adequately

sized pressure

vessel (if absent)

and/or check for

proper precharge

Faulty or

defective

pressure vessel

membrane

Replace membrane

or vessel

Incorrect setting

of set pressure

and restart

pressure

parameters

Check and set

proper parameters

(see the control

panel user manual)

PUMP

DISPRIMED*

Faulty or

malfunctioning air

supply unit

Replace air supply

unit

LACK OF

WATER-AIR

EXCHANGE*

Air supply suction

valve blocked

Clean valve of

possible limescale

or replace air supply

unit

* Valid only for GP installation with air feeders on systems with

diaphragmless tanks and/or liquid assemblies

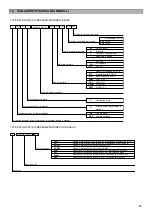

11.4. CALIBRATING THE PRESSURE SWITCHES

The pressure switches are only present in sets with an EP, SP-

EFC or SP-MFC control panel.

The pressure switches are calibrated (at ambient temperature)

according to the following standard table:

Pressure switch calibration table:

Pump

sequence

Type of

operation

Calibrating

pressures

[bar]

Sets

Pump no. 1

(or pilot pump)

Pressure switch

no. 1

Stop

P1=P0-10%

Sets with

1 pump

Start

P2=P1-

Pmin

Pump no. 2

Pressure switch

no. 2

Stop

P3=P1-0.5

Sets with

2 pumps

Start

P4=P3-

Pmin

Pump no. 3

Pressure switch

no. 3

Stop

P5=P3-0.5

Sets with

3 pumps

Start

P6=P5-

Pmin

Pump no. 4

Pressure switch

no. 4

Stop

P7=P5-0.5

Sets with

4 pumps

Start

P8=P7-

Pmin

With:

P0 = max pressure in bar of pump no. 1 (or pilot pump) with

the opening closed

P1 - P8 = calibrating pressures in bar (see the following table)

ΔP = minimum differential in bar (see the following table)

NB: depending on the characteristics of certain types of pumps

(with flat curve), the pressure switch for pump no.1 (or pilot)

may be calibrated at a stopping pressure P1= P0

– 0.3 bar Any

diaphragm tanks must be calibrated by the user at a pressure

Содержание GP

Страница 2: ......

Страница 21: ...20 COLLEGAMENTO A QUADRO DI PROTEZIONE INVERTER A BORDO MOTORE VASCO E SPD H PRESSOSTATO DI AVVIAMENTO POMPA...

Страница 43: ...19 ENGLISH PROTECTION PANEL CONNECTION WITH ON BOARD PUMP INVERTER VASCO E SPD H PUMP STARTING PRESSURE SWITCH...

Страница 48: ...24 ENGLISH 18 UKCA DECLARATION OF CONFORMITY...