Setup ■ Setting Up Input and Output Media

- 52 -

Data I/O ■ 096-0465-001C

9c.

Use the Cover Tape Position Adjuster if needed. Turning it

clockwise moves the cover tape position toward the sprocket

side of the tape.

9d.

Using blue tabbing tape, attach the cover tape to the carrier

tape. Thread both through the cover tape Guide Sealer

Assembly. Run the machine to advance the carrier and

cover tapes through the sealer.

P

REPARE THE

S

EAL

Note:

Disable the pressure seal by loosening the seal roller pressure

screws until the seal rollers are no longer in contact with the cover tape.

Normally the heat switch is in on position. If not, turn on the heat switch.

To prepare the heat seal

1.

Set the temperature controls to the appropriate temperature. See

the table below.

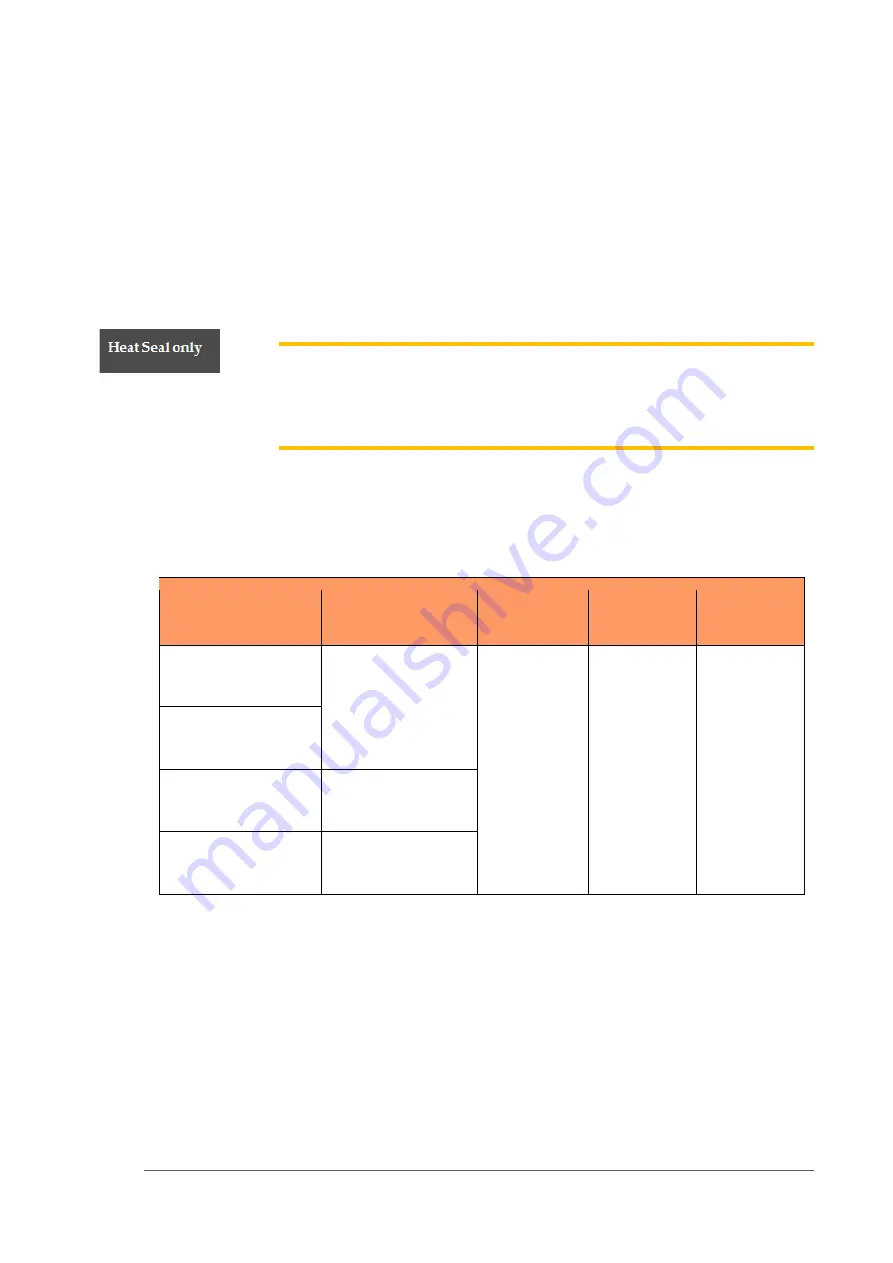

Carrier Tape Type

Cover Tape Type

Temperatur

e

Air

Pressure

Dwell Time

3m Type 3000

Conductive Carrier

3m Type 2675 Static

Dissipative Cover

135-155°C

40-60 PSI

250-400 ms

3m Type 2701/2703

Non-conductive

Advantek

Conductive

Advantek Type AA

Advantek

Non-conductive

Advantek Type S

Figure 29:

This table lists suggested temperature and pressure

settings for the Tape Output. The temperature of each shoe can

be increased or decreased according the results of a peel force

test.

2.

Adjust the heat shoe air pressure to the appropriate setting. This

setting controls the amount of force applied when the sealer shoes

drop.

Содержание PSV5000

Страница 12: ......

Страница 36: ......

Страница 160: ......

Страница 161: ...Electrical Schematics for PSV5000 and Equipment ...

Страница 162: ......

Страница 163: ......

Страница 164: ......

Страница 165: ......

Страница 166: ......

Страница 167: ......

Страница 168: ......

Страница 169: ......

Страница 170: ......

Страница 171: ......

Страница 172: ......

Страница 173: ......

Страница 174: ......

Страница 175: ......

Страница 176: ...PROGRAMMABLE MEDIA EXPERTS ...