Optyma Plus

TM

User

Guide RS8GD602 © Danfoss 2015-10

5

Data communication

The controller is delivered with built-in MODBUS data

communication.

If a different form of data communication is requested, a LON RS-

485 module can be inserted in the controller.

The connection will then be made on terminal RS 485.

Important

All connections to the data communication must comply with the

requirements for data communication cables.

See literature: RC8AC.

Display

The controller has one plug for a display. Here display type EKA

163B or EKA 164B (max. length 15m) can be connected.

EKA 163B is a display for readings.

EKA 164B is both for readings and operation.

The connection between display and controller must be with a

cable which has a plug at both ends.

A setting can be made to determine whether the Tc or Ts is to be

read out. When the value is read out, the second read-out can be

displayed by briefly pressing the lower button.

When a display is to be connected to the built-in MODBUS, the

display can advantageously be changed to one of the same type,

but with Index A (version with screw terminals).

The controllers address must be set higher than 0 in order for the

display to be able to communicate with the controller.

If connection of two displays is required, one must be connected

to the plug (max. 15 m) and the other must then be connected to

the fixed data communication.

Override

The controller contains a functions which can be used together

with the override function in the master gateway/system man-

ager.

Heating element in the crankcase

The controller has a thermostat function which can control the

heating element for the crankcase. Oil can thus be kept separate

from the refrigerant. The function is active when the compressor

has stopped.

The function is based on the ambient temperature and suction

gas temperature. When the two temperatures are equal ± a

temperature difference, power will be supplied to the heating

element.

The 'CCH off diff' setting indicates when power will no longer be

supplied to the heating element.

The 'CCH on diff' indicates when 100% power will be sent to the

heating element.

Between the two settings the controller calculates the wattage

and connects to the heating element in a pulse/pause cycle which

corresponds to the desired wattage.

The Taux sensor can be used to record the temperature in the

crankcase if desired.

When the Taux sensor records a temperature lower than Ts+10 K,

the heating element will be set to 100%, but only if the ambient

temperature is below 0°C.

Digital inputs

There are two digital inputs DI1 and DI2 with contact function and

one digital input DI3 with high voltage signal.

They can be used for the following functions:

DI1: Starts and stops compressor

DI2: Here the user can select from various functions

Status notification from an external safety function

External main switch

Night setback signal

Separate alarm function

Monitoring of input signal

DI3: Safety signal from low/high-pressure switch

Function via data communication

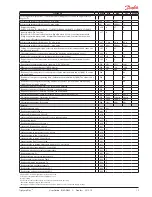

Day/Night schedule

Function in gateway/system manager

Day/Night control / Time

schedule

Used parameters in OptymaPlus

--- Night setback

Address o03 > 0