Optyma Plus

TM

User

Guide RS8GD602 © Danfoss 2015-10

9

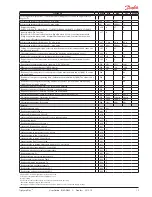

Select signal for the display

Here you define the signal to be shown by the display.

1: Suction pressure in degrees, Ts.

2: Condensing pressure in degrees, Tc.

o17

Display mode

Pressure transmitter settings for Ps

Working range for pressure transmitter - min. value

o20

MinTransPs

Pressure transmitter settings for Ps

Working range for pressure transmitter - max. value

o21

MaxTransPs

Refrigerant setting

(only if "r12" = 0)

Before refrigeration is started, the refrigerant must be defined. You may choose be-

tween the following refrigerants

2=R22. 3=R134a. 13=User defined. 17=R507. 19=R404A. 20=R407C. 21=R407A.

37=R407F.

Warning: Wrong selection of refrigerant may cause damage to the compressor.

Other refrigerants: Here Setting 13 is selected and then three factors -Ref.Fac a1, a2

and a3 - via AKM must be set.

o30

Refrigerant

Digital input signal - D2

The controller has a digital input 2 which can be used for one of the following func-

tions:

0: The input is not used.

1: Status display from an external safety function (short-circuited =ok for compressor

operation)

2: Main switch. Regulation is carried out when the input is short-circuited, and regula-

tion is stopped when the input is put in pos. OFF.

3: Night operation. When the input is short-circuited, there will be regulation for night

operation.

4: Separate alarm function. Alarm will be given when the input is short-circuited.

5: Separate alarm function. Alarm will be given when the input is opened.

6: Input status, on or off. (DI2 status can be tracked via data communication)

7: Alarm from the compressor's external speed control.

o37

DI2 config.

Pressure transmitter settings for PC

Working range for pressure transmitter - min. value

o47

MinTransPc

Pressure transmitter settings for PC

Working range for pressure transmitter - max. value

o48

MaxTransPc

Select the type of condensing unit.

Factory set.

After the first setting, the value is 'locked' and can only be changed once the control-

ler has been reset to its factory setting.

When entering the refrigerant setting, the controller will ensure that the 'Unit type'

and refrigerant are compatible.

o61

Unit type

S3 Configuration

0 = S3 input not used

1 = S3 input used for measuring of discharge temperature

o63

S3 config

Save as factory setting

With this setting you save the controller’s actual settings as a new basic setting (the

earlier factory settings are overwritten).

o67

-

Define the use of the Taux sensor (S5)

0: Not used

1: Used to measure oil temperature

2: Other use. Measuring of optional temperature.

o69

Taux Config

Period time for heating element in crankcase

Within this period the controller will itself calculate an OFF and ON period.

The time is entered in seconds.

P45

PWM Period

Difference for the heating elements 100% ON point

The difference applies to a number of degrees below the 'Tamb minus Ts = 0 K' value.

P46

CCH_OnDiff

Difference for the heating elements full OFF point

The difference applies to a number of degrees above the 'Tamb minus Ts = 0 K' value

P47

CCH_OffDiff

Operating time for condensing unit

The condensing unit's operating time can be read out here. The read-out value must

be multiplied by 1,000 in order to obtain the correct value.

(The displayed value can be adjusted if required)

P48

Unit Runtime

Operating time for the compressor

The compressors operating time can be read out here. The read-out value must be

multiplied by 1,000 in order to obtain the correct value.

(The displayed value can be adjusted if required)

P49

Comp Runtime

Operating time for heating element in crankcase

The heating element's operating time can be read out here. The read-out value must

be multiplied by 1,000 in order to obtain the correct value.

(The displayed value can be adjusted if required)

P50

CCH Runtime

Number of HP alarms

The number of HP alarms can be read out here.

(The displayed value can be adjusted if required)

P51

HP Alarm Cnt