12

User

Guide RS8GD602 © Danfoss 2015-10

Optyma

Plus

TM

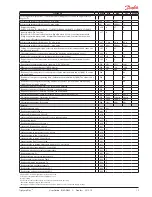

Settings from

System manager

Settings from

AKM (AKM destination)

Log

Alarm relay

Send via

Network

Non

High

Low-High

High

1

X

X

X

X

Middle

2

X

X

X

Low

3

X

X

X

Log only

X

Disabled

Fault message

In an error situation the LED’s on the front will flash and the alarm relay will be activated. If you push the top button in this situation you can see the

alarm report in the display.

There are two kinds of error reports - it can either be an alarm occurring during the daily operation, or there may be a defect in the installation.

A-alarms will not become visible until the set time delay has expired.

E-alarms, on the other hand, will become visible the moment the error occurs.

(An A alarm will not be visible as long as there is an active E alarm).

Here are the messages that may appear:

Code / Alarm text via data

communication

Description

Action

A2/--- LP alarm

Low suction pressure

See instructions for the condensing unit

A11/--- No Rfg. sel.

No refrigerant selected

Set o30

A16 /--- DI2 alarm

DI2 alarm

Check the function that sends a signal at the DI2 input

A17 / ---HP Alarm

C73 / DI3 Alarm (High / low pressure alarm)

See instructions for the condensing unit

A45 /--- Standby mode

Standby position (stopped refrigeration via r12 or DI1-input)

r12 and/or DI1 input will start the regulation

A80 / --- Cond. blocked

Air flow has decreased.

Clean the condensing unit

A96 / --- Max Disc. Temp

Discharge gas temperature is exceeded

See instructions for the condensing unit

A97 / --- Safety alarm

Safety function on DI2 is activated

Check the function that sends a signal at the DI2 input

and the direction of rotation of the compressor

A98 / --- Drive alarm

Alarm from speed regulation

Check speed regulation

E1 /--- Ctrl. Error

Faults in the controller

Check sensor and connection

E20 /--- Pc Sensor Err

Error on pressure transmitter Pc

E30 /--- Taux Sensor Err

Error on Aux sensor, S5

E31/---Tamb Sensor Err

Error on air sensor, S2

E32 / ---Tdis Sensor Err

Error on discharge sensor, S3

E33 / ---Tsuc Sensor Err

Error on suction gas sensor, S4

E39/--- Ps Sensor Err

Error on pressure transmitter Ps

Data communication

The importance of individual alarms can be defined with a setting. The setting must be carried out in the group "Alarm destinations"