6

User

Guide RS8GD602 © Danfoss 2015-10

Optyma

Plus

TM

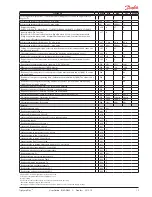

Survey of functions

Function

Para-

meter

Parameter by operation via data

communication

Normal display

The display shows the temperature value for the suction pressure Ts or from the con-

densing pressure Tc. Enter which of the two are to be displayed in o17.

During operation, when one of the two is shown in the display, the other value can be

seen by pressing and holding in the lower button.

Ts / Tc

Thermostat

Thermostat control

Set point

The controller's reference Tc is the outside tempe set point + any applicable

offset.

Enter the set point by pressing the middle button. A offset can be entered in r13.

Reference

Unit

Set here if the display is to show SI-units or US-units

0: SI (°C and bar)

1: US (°F and Psig).

r05

Unit

°C=0. / °F=1

(Only °C on AKM, whatever the set-

ting)

Start / stop of refrigeration

With this setting refrigeration can be started, stopped or a manual override of the

outputs can be allowed. (For manual control the value is set at -1. Then the relay out-

lets can be force-controlled by the respective reading parameters (u58, u59 etc.). Here

the read value can be overwritten.)

Start / stop of refrigeration can also be accomplished with the external switch func-

tion connected to a DI input.

If the external switch function is deselected, the input must be shorted.

Stopped refrigeration will give a ”Standby alarm”.

r12

Main Switch

1: Start

0: Stop

-1: Manual control of outputs allowed

Night setback value

The controller reference is raised by this value when the controller switches to night

operation.

r13

Night offset

Reference Ts

Here the reference is entered for the suction pressure Ts in degrees.

r23

Ts Ref

Reference Tc

Here the current controller reference for condensing pressure Tc can be read out in

degrees.

r29

Tc Ref

Minimum condensing temperature

(lowest permitted regulation reference)

Here the lowest permitted reference is entered for the condensing temperature Tc.

r82

MinCondTemp

Maximum condensing temperature

(highest permitted regulation reference)

Here the highest permitted reference is entered for the condensing temperature Tc.

r83

MaxCondTemp

Maximum discharge gas temperature

Here the highest permitted discharge gas temperature is entered. The temperature

is measured by sensor Td. If the temperature is exceeded, the fan will be started at

100%. A timer is also started which can be set in c72. If the timer setting runs out,

the compressor will be stopped and an alarm will be issued. The compressor will be

reconnected 10 K below the cut-out limit, but only after the compressor's off timer

has expired.

r84

MaxDischTemp

Night setbck

(start of night signal. 0=Day, 1=Night)

Alarm

Alarm settings

The controller can give alarm in different situations. When there is an alarm all the

light-emitting diodes (LED) will flash on the controller front panel, and the alarm relay

will cut in.

With data communication the impor-

tance of the individual alarms can be

defined. Setting is carried out in the

“Alarm destinations” menu via AKM.

Delay of a DI2 alarm

A cut-out/cut-in input will result in alarm when the time delay has been passed. The

function is defined in o37

A28

AI.Delay DI2

High condensing temperature

The limit value (difference over normal reference) to which the condensing tempera-

ture has increased, and at which an alarm must be issued. Can be set in K.

A70

Air flowDiff

Delay time for alarm A70. Set in minutes.

A71

Air flow del

Reset alarm

Ctrl. Error