Optyma Plus

TM

User

Guide RS8GD602 © Danfoss 2015-10

17

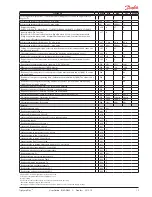

Data

Supply voltage

230 V a.c. +10/-15 %. 5 VA, 50 Hz

Sensor S2, S3,

S4, S5,

Pt 1000

Accuracy

Measuring range -60 to +120°C

(S3 to 150°C)

Controller

±1 K below -35°C

± 0.5 K between -35 to +25°C;

±1 K above +25°C

Pt 1000 sensor

±0.3 K at 0°C

±0.005 K per grad

Measuring of

Pc, Ps

Pressure trans-

mitter

Ratiometric. eg. AKS 32R

Display

LED, 3-digits

External display EKA 163B or 164B (any EKA 163A or 164A)

Digital inputs

DI1, DI2

Signal from contact functions

Requirements to contacts: Gold plating

Cable length must be max. 15 m

Use auxiliary relays when the cable is longer

Digital input DI3 230 V a.c. from safety pressostat. Low/high pressure

Electrical con-

nection cable

Max.1.5 mm

2

multi-core cable

Triac output

Fan

Max. 240 V a.c. , Min. 28 V a.c.

Max. 2.0 A

Leak < 1 mA

Relays*

CE

(250 V a.c.)

Comp, CCH

4 (3) A

Alarm, Fan, Aux

4 (3) A

Analog output

2 pcs. 0-10 V d.c.

(For external speed control of fans and compressors)

Min. load = 10 K ohm. (Max. 1 mA)

Environments

-25 to +55°C, During operations

-40 to +70°C, During transport

20 - 80% Rh, not condensed

No shock influence / vibrations

Density

IP 20

Mounting

DIN-rail or wall

Weight

0.4 Kg

Data communi-

cation

Fixed

MODBUS

Extension options

LON

Power reserve

for the clock

4 hours

Approvals

EC Low Voltage Directive and EMC demands re CE-

marking complied with

LVD tested acc. EN 60730-1 and EN 60730-2-9, A1, A2

EMC-tested acc. EN 61000-6-2 and EN 61000-6-3

* Comp and CCH are 16 A relays. Alarm and Fan are 8 A relays. Max. load must be observed

Capacitive load

The relays cannot be used for the direct connection of capacitive loads such as LEDs and on/off

control of EC motors.

All loads with a switch mode power supply must be connected with a suitable contactor or simi-

lar.