Optyma Plus

TM

User

Guide RS8GD602 © Danfoss 2015-10

15

continued

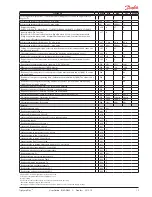

Code

Min.

Max.

Fac.

Actual

*) Can only be set when regulation is stopped (r12=0)

**) Can be controlled manually, but only when r12=-1

Select signal for display view. 1=Suction pressure in degrees, Ts. 2=Condensing pressure in

degrees, Ts

o17

1

2

1

Pressure transmitter working range Ps - min. value

o20

-1 bar

5 bar

-1

Pressure transmitter working range Ps- max. value

o21

6 bar

200 bar

12

Refrigerant setting:

2=R22. 3=R134a. 13=User defined. 17=R507. 19=R404A. 20=R407C. 21=R407A. 37=R407F

*

o30

0

37

0

Input signal on DI2. Function:

(0=not used, 1=External safety function. Regulate when closed, 2=external main switch,

3=Night operation when closed, 4=alarm function when closed, 5=alarm function when

open. 6=on/off Status for monitoring.

o37

0

6

0

Pressure transmitter working range Pc– min. value

o47

-1 bar

5 bar

0 bar

Pressure transmitter working range Pc – max. value

o48

6 bar

200 bar

32 bar

Setting of condensing unit type (is factory set when the controller is mounted and cannot be

subsequently changed)

*

o61

0

45

0

The sensor input S3 is to be used to measure the discharge gas temperature (1=yes)

o63

0

1

1

Replace the controllers factory settings with the present settings

o67

Off

On

Off

Defines the use of the Taux sensor: 0=not used; 1=measuring of oil temperature; 2=other

optional use

o69

0

2

0

Period time for heating element in crankcase (ON + OFF period)

P45

30 s

255 s

240 s

Difference for heating elements 100% ON point

P46

-20 K

-5 K

-10 K

Difference for heating elements 100% OFF point

P47

5 K

20 K

10 K

Read-out of operating time for condenser unit. (Value must be multiplied by 1,000). The value

can be adjusted.

P48

-

-

0 h

Read-out of compressor operating time. (Value must be multiplied by 1,000). The value can be

adjusted.

P49

-

-

0 h

Read-out of operating time of heating element in crankcase. (Value must be multiplied by

1,000). The value can be adjusted.

P50

-

-

0 h

Read-out of number of HP alarms. The value can be adjusted.

P51

-

-

0

Read-out of number of LP alarms. The value can be adjusted.

P52

-

-

0

Read-out of number of Td alarms. The value can be adjusted.

P53

-

-

0

Oil return management. Compressor speed for the counter starting point

P77

25 Hz

70 Hz

40 Hz

Oil return management. Limit value for counter

P78

5 min.

720 min. 20 min.

Oil return management. Boost-speed

P79

40 Hz

100 Hz

50 Hz

Oil return management. Boost-time.

P80

10 s

600 s

60 s

Service

Readout pressure on Pc

u01

bar

Readout temperature Taux

u03

°C

Status on DI1 input. 1=on=closed

u10

Status on night operation (on or off) 1=on=night operation

u13

Readout superheat

u21

K

Readout temperature at S6 sensor

u36

°C

Status on DI2 input. 1=on=closed

u37

Readout the compressor capacity in %

u52

%

Status on relay to compressor. 1=on=closed

** u58

Status on relay to fan. 1=on=closed

** u59

Status on relay to alarm. 1=on=closed

** u62

Status on relay "Aux". 1=on=closed

** u63

Status on relay to heating element in crank case. 1=on=closed

** u71

Status on high voltage input DI3. 1=on=230 V

u87

Readout condensing pressure in temperature

U22

°C

Readout pressure Ps

U23

bar

Readout suction pressure in temperature

U24

°C

Readout ambient temperature Tamb

U25

°C

Readout discharge temperature Td

U26

°C

Readout suction gas temperature Ts

U27

°C

Readout the voltage on the output AO1

U44

V

Readout the voltage on the output AO2

U56

V

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep upper and lower button depressed at the same time as you reconnect the supply voltage