O p e r a t i o n l

4 - 3 5

4

Opera

tion

O p e r a t i n g S c r e e n s

( c o n t i n u e d )

For additional component hoppers, a [Previous/Next] button is available to view the addi-

tional components hoppers.

For each component hopper, there is a row of possible data entry values for the hopper.

Based on the configuration of the system, not all data entry fields may be present. Use the

[Previous/Next] button to show additional component hoppers.

•

Material Density:

If (Material Density in Recipe) is enabled, and (Resin Codes) are

disabled, this data entry field will be presented. For each component hopper, the oper-

ator can enter the material’s solid density value (g/cc).

•

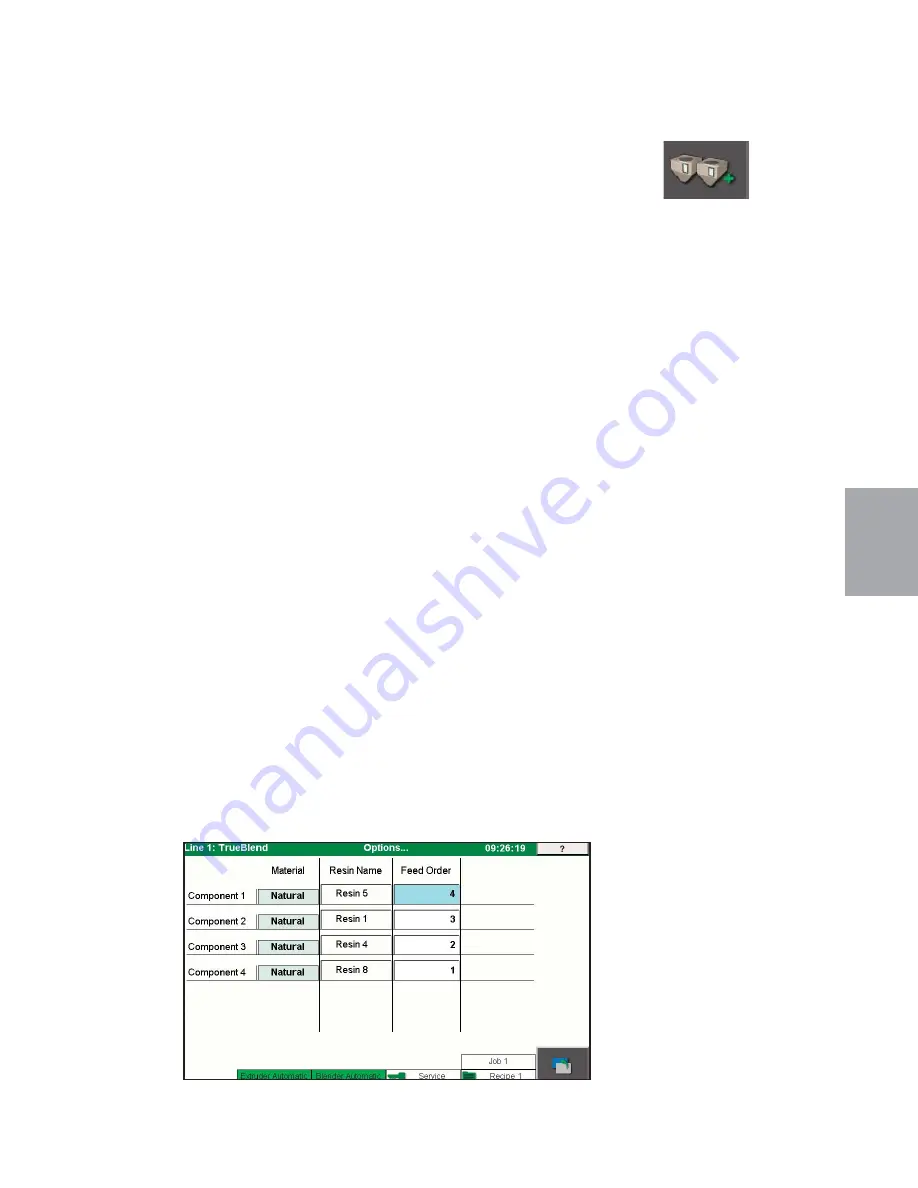

Resin Codes:

If (Use Resin Names) is enabled, this data field will be presented. When

touched, a popup is presented where the operator can select the Resin that will be

available in the hopper. The system maintains a list of 255 resins which can be indi-

vidually defined. When a resin is selected from the list, the popup will be closed, and

the resin name will be displayed on the <Options> screen. The selected resin will now

also be shown on the main blender monitor screen in place of the material type field.

Note: When using Resin Codes, the resins solid density is defined and will be used if

needed.

•

Feed Order:

If (Feed Order in Recipe) is enabled, this data entry field is present. The

operator can enter the desired feed sequence. If the sequence is entered incorrectly, a

popup will notify the operator. The feed sequence must be correct before leaving this

screen. If the [Feed Order in Recipe] is set to (NO), the [Natural] feed sequence will

be automatically selected from the smallest to largest percentage; [Regrind] is always

fed first. If the [Feed Order in Recipe] is set to (YES), the feed sequence will be

selected according to the operator’s selection. The [Regrind] component will be forced

to feed first and the operator will select a unique feed sequence for the remaining

[Natural] components.

•

Dosing Rate (g/s):

When the blender is operating purely in volumetric mode of opera-

tion, this value will determine the amount of time the gate remains open in order to

process the recipe. This data is a gram per second value. In volumetric mode, the

batch hopper is not being weighed and there is no verification that the batch process-

ing is accurate. The system is purely relying on the dosing rate value to feed material.

If this value is incorrect, the mix will be wrong. In this mode, variations in bulk densi-

ty and flow rate are not accounted for.

(Continued)

Содержание TrueBlend SB-4

Страница 6: ...iv l Table of Contents...

Страница 38: ...3 10 l Installation...

Страница 134: ...4 96 l Operation...

Страница 160: ...6 10 l Troubleshooting...

Страница 165: ...Appendix l C 2 Hole Locations for Blow Off Kit...

Страница 168: ...D 3 l Appendix...