Page 14

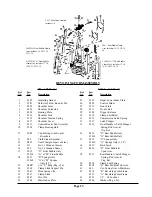

INSTRUCTIONS FOR LUBRICATING BEARING SURFACES

WITHIN FORM FINISHER

(Form Finisher Serial No. 1903 To ----)

NOTE:

Inspect bearing areas at least every 30 days. If an

accumulation of lint is evident, bearing surfaces must be

cleaned and lubricated.

FIRST:

Lift revolving form up and off of steam chamber.

SECOND: Sand off old lubricant, or foreign matter, from bearing

surfaces A and A1.

THIRD:

Wipe dust and lint off of surfaces A, A1, B, B1, C and D.

FOURTH:

Spread DOW CORNING VALVE SEAL A (Heat Stabile

Silicon Lubricant) with a piece of cardboard over surface A,

and apply to bearing points C and D. With Finger, pack inside of

dome above ball bearing B1 with Valve Seal A.

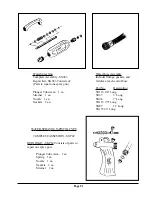

TO REPLACE METALLIC STEAM SPREADER

(Form Finisher Serial No. 100 To ----)

FIRST:

Remove old metallic spreader if it fails to diffuse

steam properly.

SECOND: Fold new copper mesh L over, three times, into

approximately a 1 1/2 width band, 18 long.

THIRD:

Wrap copper mesh tightly around valve body.

FOURTH: Place perforated brass draw band with ring M

around copper mesh. Feed end of band through

ring and pull band tight. Fold band back over

ring with a pair of pliers to keep band tight.

(For Form Finisher S.N. 100 to ----)

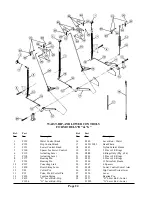

INSTRUCTIONS FOR LUBRICATING BEARING

POINTS ON OUTSIDE OF BASE

Wipe bearing surfaces clean and oil with a lightweight oil,

at least every 60 days.

NOTE:

Nylon bearings do not require lubrication.

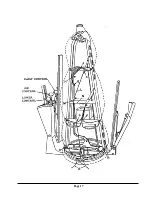

STEAM CHAMBER

REVOLVING FORM

Содержание FFCD

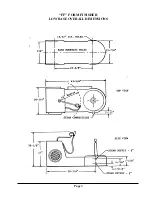

Страница 3: ...Page 3 FF FORM FINISHER LOW BASE OVERALL DIMENSIONS...

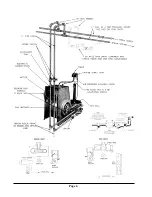

Страница 6: ...Page 6...

Страница 16: ...Page 16...

Страница 17: ...Page 17...

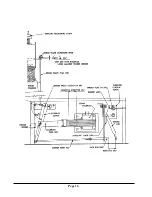

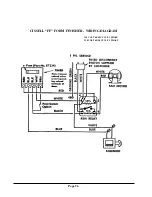

Страница 26: ...Page 26 CISSELL FF FORM FINISHER WIRING DIAGRAM 110 VOLT 60 50 CYCLE 1 PHASE 220 VOLT 60 50 CYCLE 1 PHASE...