Page 23

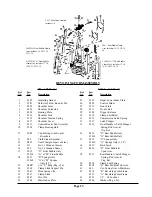

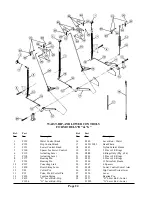

REVOLVING FORM ASSEMBLY

F22 - D Model

Ref.

Part

No.

No.

Description

1

F192

Insulating Gasket

2

F381

Shldr. Adj. Rod, Knob, & Pin

3

F492

Shoulder Form

4

F493

Shoulder Extension

5

F494

Bearing Plate

6

F336

Shoulder Link

7

F197

Shoulder Tension Spring

8

F317

Shoulder Lever

9

F533

Control Box & Pan Assembly

10

F140

Clamp Bearing Bolt

12

F289

Cup & Brng. w/bolts, nuts

& washers

13

F09

Cloth Steam Spreader

14

F842

Vent Clamp (not part of asm.)

15

F11

No. 11 Wooden Sleever

16

F24

No. 24 Wooden Shaver

17

F432

D Front Paddle Only

F1016

G or M Front Paddle

18

F433

D Sponge Only

F1018

G or M Sponge

Only (42)

19

F888*

3/16 E Ring (Pkg. of 6)

20

F240

Clamp Slide Support Pin

21

F243

Slide Spring Clip

22

F237

Clamp Slide

23

F267

Pivot Pin

24

F304

Waist Index Plate

F1007 - G Model

Ref.

Part

No.

No.

Description

25

F303

Hip & Lower Index Plate

26

F302

Control Slides

27

F332

Front Plate

28

F333

Front Latch

29

F104

Trigger Release

30

F335

Clamp Latch Rod

31

F151

Compression Latch Spring

32

F137

Latch Plunger

33

F334

Front Handle w/Latch Plunger

Spring, Rod Asm. &

Trig. Rel.

34

F434

D Rear Paddle Only

F1014

G Rear Paddle Only

35

F435

D Sponge Only

F1019

G Sponge Only (3 1/2)

36

F427

Back Latch

37

F436

D Front Paddle &

Spon. Asm.

38

F437

Rear Handle w/Latch Plunger,

Spring, Rod Asm. &

Trig. Rel.

39

F218

Clamp Leaf Spring

40

F438

D Rear Paddle & Sp. Asm.

41

F63

Cov. Spring Asm. w/Hardware

42

F534

D Revolving Form Frame

F535

G Revolving Form Frame

43

F122

1/4 - 28 Locknut

44

P104

Washer (Pkg. of 6)

F517 - Shoulder Assembly

includes 1-8.

F862WH - Front Paddle Clamp

Asm. includes: 19, 20, 21, 22,

33, 37, 39.

F1012WH - G Front Paddle

Clamp Assy. includes 17, 18,

19, 20, 21, 22, 33, 39.

F861 - Rear Paddle Clamp

Asm. includes: 19, 23, 38, 39,

40.

F1011WH - G Rear Paddle

Clamp Assy. includes 17, 18,

19, 23, 38, 39, 34, 35.

Содержание FFCD

Страница 3: ...Page 3 FF FORM FINISHER LOW BASE OVERALL DIMENSIONS...

Страница 6: ...Page 6...

Страница 16: ...Page 16...

Страница 17: ...Page 17...

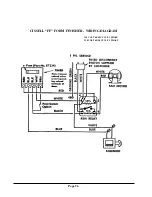

Страница 26: ...Page 26 CISSELL FF FORM FINISHER WIRING DIAGRAM 110 VOLT 60 50 CYCLE 1 PHASE 220 VOLT 60 50 CYCLE 1 PHASE...