Page 28

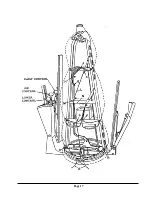

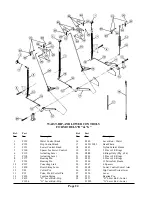

INSTALLATION OF MOTOR AND BLOWER ASSEMBLY

FOR CISSELL FORM FINISHERS

INSTALLATION OF BLOWER

A.

Place Blower Wheel in housing with blades

at bottom cupped towards opening.

(See illustration on other side)

B.

Install cut-off sheet.

C.

Slip Shaft through center holes of Housing

and Blower Wheel.

D.

Align Blower Wheel equidistant from each

side of Housing with equal lengths of shaft

extending beyond each side of Housing.

Tighten Blower Wheel Set Screw against

flat of Shaft with fingers.

NOTE

USE ONE DROP OF LIGHTWEIGHT OIL IN HOLE OF

EACH BEARING BEFORE INSERTING ON SHAFT.

E.

Install Bearing Insulator, Bearing Assembly,

and Plastic Thrust Washer on each end of

Shaft, as illustrated. Also install Thrust

Collar as illustrated. Tighten Set Screw of

Thrust Collar and Center Blower Wheel Set

Screw with a wrench.

F.

Slip Large Pulley on Blower Wheel Shaft

against Plastic Thrust Washer with Set

Screw outside. Tighten securely.

NOTE

SEE INSTRUCTIONS FOR ALIGNMENT

AND PROPER BELT TENSION.

INSTALLATION OF MOTOR

NOTE

CONDENSER MUST BE REMOVED BEFORE RE-

MOVING OR INSTALLING MOTOR.

A.

Install Motor Support Bar and Adjusting

Bolt on Motor before installing Motor in

Housing

B.

Place Motor in position and secure with

bolts in each end of Support Bar.

C.

Slip Small Pulley on Motor Shaft with Set

Screw out away from Motor. Have end of

Pulley flush with end of Shaft.

ALIGNMENT OF PULLEYS

NOTE

IF INSTALLATION HAS BEEN MADE

ACCORDING TO INSTRUCTIONS THE BELT ALIGN-

MENT SHOULD BE CORRECT. IF THERE SHOULD

BE ANY DOUBT, CHECK THE FOLLOWING IN-

STRUCTIONS.

A.

Place a straight edge against face of Large

Pully and align face of Small Pulley with

straight edge. Move Small Pulley for

adjustment. (Fig. 2)

B.

To put tension on belt turn Adjustment Bolt

Clockwise. (Use wrench) Hold bolt with

wrench, tighten Square Lock Nut clockwise

with a wrench.

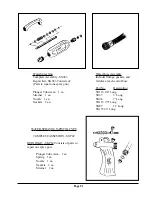

BLOWER BELT SETTING EXTREMELY IMPORTANT

Improper belt tension and misalignment develop bearing

and belt failures.

FIGURES 1 and 2 deal with proper tension and correct

alignment of belts and pulleys when used on blower

applications.

FIGURE 1 indicates the recommended tension, deter-

mined by grasping the belt as shown and when a normal

pressure is applied, a deflection of approximately 1 in

the belt will occur.

If the deflection is much in excess of that indicated, belt

slippage may occur and excessive belt wear can result.

If the deflection is somewhat less than indicated, the belt

is too tight and will shorten the life of the bearing.

Excessive tension will actually pull the shaft through the

oil film in the bearing and allow metal to metal contact.

In addition to decreasing the bearing life, it will contrib-

ute to noisy blower operation. Any defects in the belt or

pulleys will be exaggerated.

FIGURE 2 deals with a recommended method for

checking correct alignment of pulleys. Excessive

misalignment produces increased belt wear and can

produce lateral motion of the wheel and shaft to the point

that considerable noise can develop.

Содержание FFCD

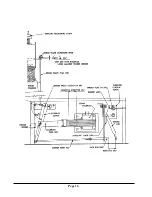

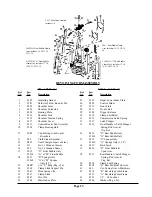

Страница 3: ...Page 3 FF FORM FINISHER LOW BASE OVERALL DIMENSIONS...

Страница 6: ...Page 6...

Страница 16: ...Page 16...

Страница 17: ...Page 17...

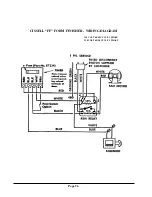

Страница 26: ...Page 26 CISSELL FF FORM FINISHER WIRING DIAGRAM 110 VOLT 60 50 CYCLE 1 PHASE 220 VOLT 60 50 CYCLE 1 PHASE...