Chapter 1

1-106

[Caution] When you are not loading tab paper, make sure to return the Tab Feeding Attachment-F1 to its holder. Using the Tab Feeding Attachment-F1 for storing

paper other than tab paper may cause a paper jam.

1.1.7.1.21 Automatic gradation adjustment for a custom paper type / Registering and Selecting Paper for Calibration /

Initializing Standard Values for Calibration

0031-5495

[ Manual-related ]

Description

If you perform automatic gradation adjustment for a custom paper type, registering a custom paper type for calibration is required beforehand. You can register

paper for calibration in the following two types of procedure.

- Use the Duplex Color Image Reader Unit-H1

In this procedure, you need to scan the printed test pages 2 times, 1 time for base paper and 1 time for a custom paper type. You need to place test pages on the

platen glass for scanning, but it takes shorter time for the adjustment in comparison to using the Auto Gradation Sensor-A1. The number of sheets required for the

registration is 2 sheets of paper.

- Use the Auto Gradation Sensor-A1

In this procedure, the machine automatically performs the registration by printing test pages. You do not need to scan test pages, but it takes longer time for the

registration in comparison to using the Duplex Color Image Reader Unit-H1. The number of sheets required for the adjustment is 4 sheets of paper. Two basis paper

and two custom paper type to calibrate is output for test pages.

Field Remedy

[Caution]

- If both the Duplex Color Image Reader Unit-H1 and the Auto Gradation Sensor-A1 are attached, select the automatic gradation adjustment method you use in

"Select Method" beforehand. Select "Use Scanner" to use the Duplex Color Image Reader Unit-H1 or "Do Not Use Scanner" to use the Auto Gradation Sensor-A1.

- Confirm that both paper to use as a basis and a custom paper type to register to adjust, described in the following table, are set in paper sources correctly before

starting this procedure.

Basic paper / Custom paper type

a) Registering Paper for Calibration

1) Press Settings/Registration > Adjustment/Maintenance > Adjust Image Quality > Auto Adjust Gradation > press Register Paper to adjust > select the destination

for registering new paper to adjust > press "Next".

[Reference] You can register up to three type of paper to adjust and you can overwrite them. When overwriting, you cannot restore the paper settings previously

registered.

2) Select the type for the paper to use as a basis > press "Next".

3) Select the paper source contains the type of paper to use as a basis > press "Next".

[Reference] This machine adjusts the toner and print speed according to the paper type. To make effective adjustments, select the correct paper type.

4) Press "Start Printing". First test page is output.

If you are using the Auto Gradation Sensor-A1, steps 5) to 6) are not necessary. Proceed to step 7).

5) Place the first test page face down on the platen glass, with the black bar along the top back edge of the platen glass. Press "Start Scanning".

6) Remove the first test page from the platen glass.

7) Select the paper source that contains the custom paper type to adjust > press "Next".

[Reference] This machine adjusts the toner and print speed according to the paper type. To make effective adjustments, select the correct paper type.

8) Press "Start Printing". Second test page is output.

If you are using the Auto Gradation Sensor-A1, the following steps are not necessary.

9) Place the second test page face down on the platen glass, with the black bar along the top back edge of the platen glass. Press "Start Scanning".

10) Remove the second test page from the platen glass.

b) Selecting Paper for Calibration

You can select the type of paper for calibration.

1) Press Settings/Registration > Adjustment/Maintenance > Adjust Image Quality > Auto Adjust Gradation.

2) Press "Select Paper to Adjust" > select the type of paper to adjust > press "OK".

[Caution]

- This machine adjusts the toner and print speed according to the paper type. To make effective adjustments, select the correct paper type.

- To perform the auto gradation adjustment to some custom paper type, select that custom paper type, which is registered in advance, for paper to adjust.

c) Changing Adjustment Level

You can change the adjustment level for auto gradation adjustment.

[Reference] When you set "By Paper Type Group" for "Adjustment Level", you can select the paper type and make effective adjustments according to the paper

type that you select from "Thin 1/Plain/Heavy 1-4", "Heavy 5", or "Heavy 6".

1) Press Settings/Registration > Adjustment/Maintenance > Adjust Image Quality > Auto Adjust Gradation.

2) Press "Adjustment Level" > select the adjustment level > press "OK".

[Caution] After changing the settings, make sure to perform the automatic gradation adjustment first, and then perform the color balance adjustment as the color

balance may become unstable.

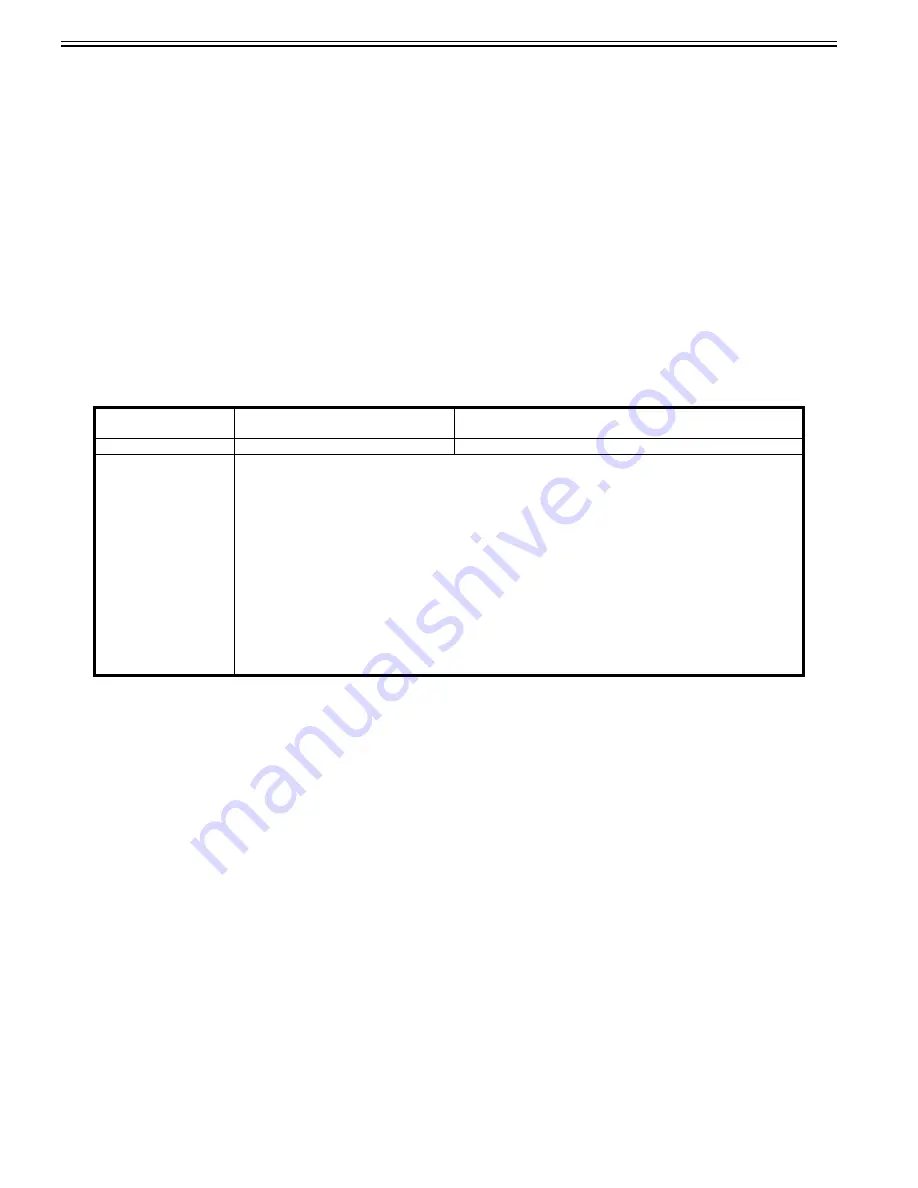

Item

When Using the Duplex Color Image Reader Unit-

H1

When Using the Auto Gradation Sensor-A1

Size

11" x 17" or A3

13" x 19", 12" x 18", 12 5/8" x 17 11/16", 11" x 17", or A3

Basis Weight/Finish/Whiteness

Paper to use as a basis:

- Hammermill Color Copy Digital (28lb. (105 g/m2))*

- Thin 1, Plain 1, Plain 2 or Heavy 1 to Heavy 6/Uncoated that has the same whiteness of the Hammermill Color Copy Digital (28lb.

(105 g/m2)) and that is already registered as paper to adjust

- Custom paper type equivalent to the above basis weight/finish/whiteness and already registered as paper to adjust

Custom paper type to register to adjust:

- Custom paper type equivalent to the basis weight/finish/whiteness of paper to use as a basis

(Before loading custom paper type, you need to register the characteristics of custom paper type and register paper source in which you

load custom paper type.

* The name of the paper is subject to change without notice. For more information, contact your local authorized Canon dealer.

Содержание imagePRESS C800 Series

Страница 1: ...Dec 2 2014 Troubleshooting Guide imagePRESS C800 Series...

Страница 2: ......

Страница 6: ......

Страница 8: ......

Страница 9: ...Chapter 1 Correcting Faulty Images...

Страница 10: ......

Страница 14: ......

Страница 71: ...Chapter 1 1 57 3 Hold the staple case by its left and right sides and lower the bracket on the staple case...

Страница 101: ...Chapter 1 1 87 1 Feeding Direction 2 Print Side Down b If you are using No 10 COM10 ISO C5 DL Monarch or Yougatanaga 3...

Страница 110: ...Chapter 1 1 96 Feeding Direction b If you are using No 10 COM10 Monarch DL ISO C5 or Yougatanaga 3...

Страница 112: ...Chapter 1 1 98 Feeding Direction b If you are using No 10 COM10 Monarch DL ISO C5 or Yougatanaga 3...

Страница 114: ...Chapter 1 1 100 7 2 Select the envelope type press OK...

Страница 165: ...Chapter 1 1 151 3 Pull the Tray all the way out...

Страница 167: ...Chapter 1 1 153 5 Remove the Waste Toner Container...

Страница 172: ...Chapter 1 1 158 2 Pull out the staple cartridge holding it by the green tab...

Страница 173: ...Chapter 1 1 159 3 Replace the staple case Remove the old staple case 1 Insert a new staple case 2...

Страница 180: ...Chapter 1 1 166 5 Push in the new staple case until it clicks to insert it...

Страница 181: ...Chapter 1 1 167 6 Close the Cover for the saddle stitch staple cartridge...

Страница 194: ...Chapter 1 1 180 4 Clean the surface A of the Fixing Inlet Guide with lint free paper 1 moistened with alcohol...

Страница 199: ...Chapter 1 1 185 b 1 Take out the Waste Toner Container 1...

Страница 201: ...Chapter 1 1 187 b 2 Install the Waste Toner Joint 1 to the Waste Toner Container 2...

Страница 202: ...Chapter 1 1 188 b 3 Put the Waste Toner Bag 1 on the Waste Toner Joint and fix it with the Waste Toner Band 2...

Страница 206: ...Chapter 1 1 192 b 9 Remove the Prism 1 1 Screw 2 1 Hook 3...

Страница 207: ...Chapter 1 1 193 b 10 Clean the toner adhered to the 2 A parts on the prism...

Страница 208: ...Chapter 1 1 194 b 11 Clean the toner adhered to the A part of the Waste Toner Container...

Страница 210: ...Chapter 1 1 196 2 Pull out the punch waste tray...

Страница 212: ...Chapter 1 1 198 3 Discard the punch waste into a receptacle Make sure that the punch waste tray is completely emptied...

Страница 216: ...Chapter 1 1 202 2 Below the stapler unit is the staple waste tray Pull out the staple waste tray...

Страница 217: ...Chapter 1 1 203 3 Discard the staple waste...

Страница 239: ...Chapter 1 1 225 3 Press Memory Media 4 Select the target memory media...

Страница 240: ...Chapter 1 1 226 5 Select the storage destination folder and then press Scan 6 Specify the desired scan settings...

Страница 250: ...Chapter 1 1 236 Select Share files and folders using SMB Windows Select the account to be used...

Страница 255: ...Dec 2 2014...

Страница 256: ......