PAGE

73

ATTENTION: After performing any manual operations on the A-B-C-N-O valves, their

factory settings must be restored or machine safety will be compromised, with the

risk of the platform potentially overturning.

3.5.3

Hydraulic failure safety devices

The hydraulic system of the lifting circuit, in the event that there is an

accidental fault in the hydraulic piping that feeds the lifting cylinders of the

work platform, features three one-way valves, normally closed (1), electrically

driven and connected directly to the cylinder, which prevents the uncontrolled

descent of the work platform from any height, thus avoiding dangerous

situations.

A manifold containing a one-way valve (1) is flanged on the upper cylinder.

A manifold containing two one-way valves (1) is flanged on the lower cylinder.

On both manifolds there is an overcentre valve set to 200 bar (2) and driven by

an external pipe.

Driving (3) these valves under pressure (¼ Gas hose) allows for the emergency

descent of the work platform.

In order to pressurise the drive, the machine features a manual pump to be used

in the event of an emergency or if the electronic control unit is not powered

(4).

(ref. Point 5.10.2 UNI EN280:2015):

Содержание 1470-HE EVO

Страница 7: ...PAGE 7...

Страница 12: ...PAGE 12 Work area on tracks Travel not allowed Maximum inclination allowed 2 5020 5490 7500...

Страница 27: ...PAGE 27...

Страница 28: ...PAGE 28...

Страница 34: ...PAGE 34 Warning Do not tighten the fixing belts too much so as not to damage the eye bolts...

Страница 50: ...PAGE 50 8 Extendible basket pedal...

Страница 57: ...PAGE 57 38 Chassis and stabilisers...

Страница 74: ...PAGE 74...

Страница 76: ...PAGE 76...

Страница 77: ...PAGE 77...

Страница 80: ...PAGE 80...

Страница 87: ...PAGE 87 Attention IT IS FORBIDDEN to block the gate in such a way as to keep access to the platform open...

Страница 137: ...PAGE 137 In this configuration the oil level B must be at a distance of 30mm from the maximum level C...

Страница 138: ...PAGE 138...

Страница 160: ...PAGE 160...

Страница 161: ...PAGE 161...

Страница 162: ...PAGE 162...

Страница 163: ...PAGE 163...

Страница 164: ...PAGE 164...

Страница 165: ...PAGE 165...

Страница 166: ...PAGE 166...

Страница 167: ...PAGE 167...

Страница 168: ...PAGE 168...

Страница 172: ...PAGE 172 6 Using the nut supplied point A 7 Move the front wheel back by pressing on the track with your foot...

Страница 178: ...PAGE 178 MANDATORY ROUTINE INSPECTIONS Date Observations Seal Signature...

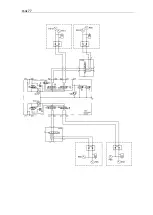

Страница 191: ...PAGE 191 8 4 Hydraulic diagram See attachment 8 5 Wiring diagram See attachment...