PAGE

128

6

Maintenance

6.1

General maintenance

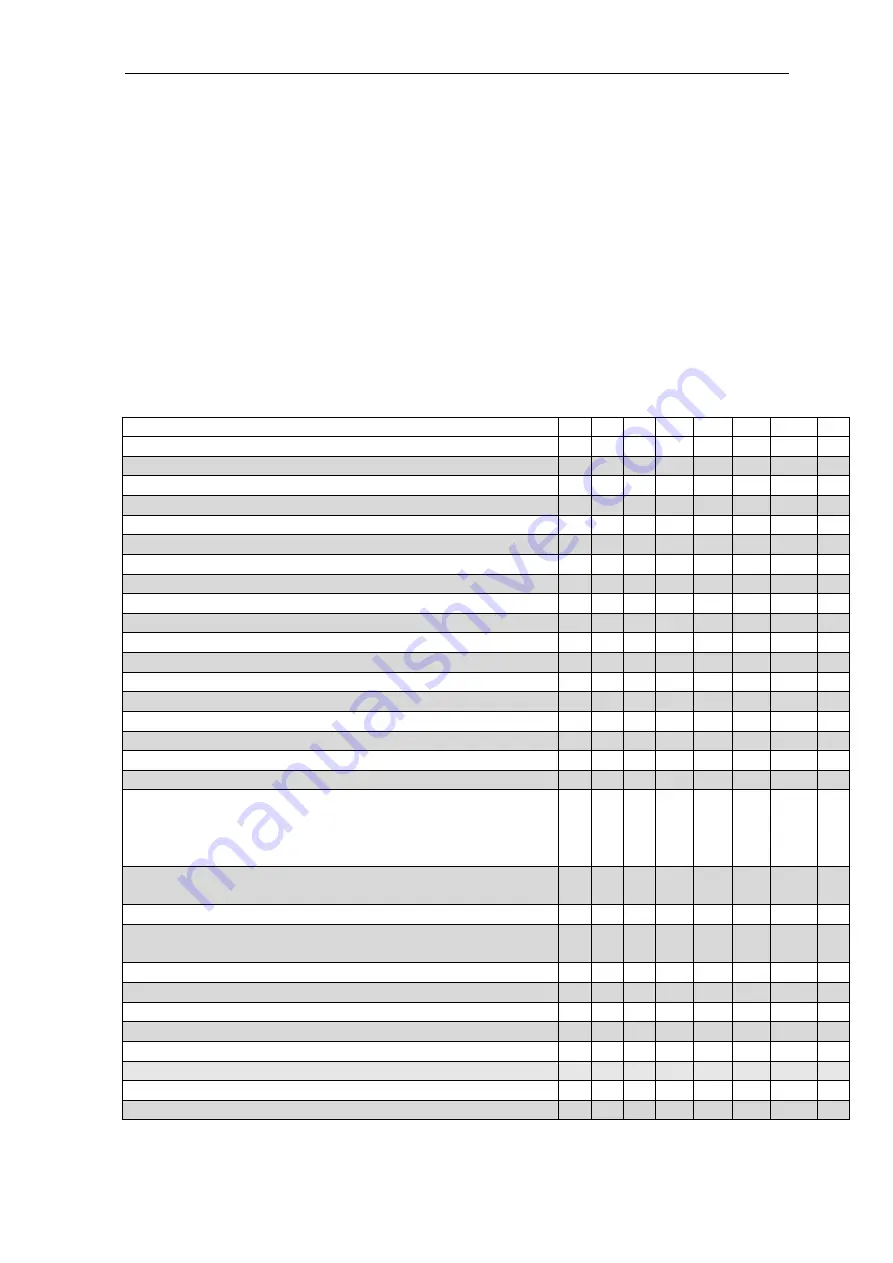

The main maintenance interventions and the frequencies with which they must

be carried out are given in the chart below.

6.1.1

Ordinary maintenance schedule table

The checks and maintenance operations must be performed as indicated in the

table below

ORDINARY MAINTENANCE SCHEDULE TABLE

A

B

C

D

E

F

G

H

10 50 100 250 500 1500

Visual and functional checks as specified

X

X

Discharge filter cartridge replacement

X

X

Suction filters replacement

X

X

Check and, if necessary, grease the runners and nylon wheels

X

X

X

Check the hydraulic oil level

X

X

Change the hydraulic oil

X

Track reduction gear oil level inspection

X

X

Replace oil in the track reduction gear

X

Check the oil level in the engine

X

X

Change the motor oil * (after the first 20 hours)

X

Replace engine oil filter.*

X

X

Clean the engine air filter.*

X

X

Replace engine air filter.*

X

Track inspection and tensioning

X

X

Check the condition of the tracks

X

X

Check the runners for wear

X

Check the tightening of nuts and bolts (general checks)

X

Check using a torque wrench the tightening of screws and bolts

for fixing of the tracked chassis to the machine frame, the

screws M16 class8.8 tightening torque 193 Nm (after the first

50 hours)

X

Check the correct positioning of the Seeger rings of the

scissors and their washers

X

X

Structural inspection (visual)

X

X

X

Structural inspection (through checking of metal parts and

welds)

X

X

Check the overload monitoring device

X

Manual emergency devices

X

X

Check the combustion engine battery

X

X

Check the correct operation of the 230V outlet differential

X

X

Check and replace the fuses

X

X

Check the maximum pressure valve

X

Check the main system angle sensors

X

X

Check the correct operation of the Sentinel

X

Содержание 1470-HE EVO

Страница 7: ...PAGE 7...

Страница 12: ...PAGE 12 Work area on tracks Travel not allowed Maximum inclination allowed 2 5020 5490 7500...

Страница 27: ...PAGE 27...

Страница 28: ...PAGE 28...

Страница 34: ...PAGE 34 Warning Do not tighten the fixing belts too much so as not to damage the eye bolts...

Страница 50: ...PAGE 50 8 Extendible basket pedal...

Страница 57: ...PAGE 57 38 Chassis and stabilisers...

Страница 74: ...PAGE 74...

Страница 76: ...PAGE 76...

Страница 77: ...PAGE 77...

Страница 80: ...PAGE 80...

Страница 87: ...PAGE 87 Attention IT IS FORBIDDEN to block the gate in such a way as to keep access to the platform open...

Страница 137: ...PAGE 137 In this configuration the oil level B must be at a distance of 30mm from the maximum level C...

Страница 138: ...PAGE 138...

Страница 160: ...PAGE 160...

Страница 161: ...PAGE 161...

Страница 162: ...PAGE 162...

Страница 163: ...PAGE 163...

Страница 164: ...PAGE 164...

Страница 165: ...PAGE 165...

Страница 166: ...PAGE 166...

Страница 167: ...PAGE 167...

Страница 168: ...PAGE 168...

Страница 172: ...PAGE 172 6 Using the nut supplied point A 7 Move the front wheel back by pressing on the track with your foot...

Страница 178: ...PAGE 178 MANDATORY ROUTINE INSPECTIONS Date Observations Seal Signature...

Страница 191: ...PAGE 191 8 4 Hydraulic diagram See attachment 8 5 Wiring diagram See attachment...