Operation, configuration and communication

42/14-39 EN

Sensyflow iG, Version 1.00

39

7.4.4

Entering and changing data

7.4.5

Status signals

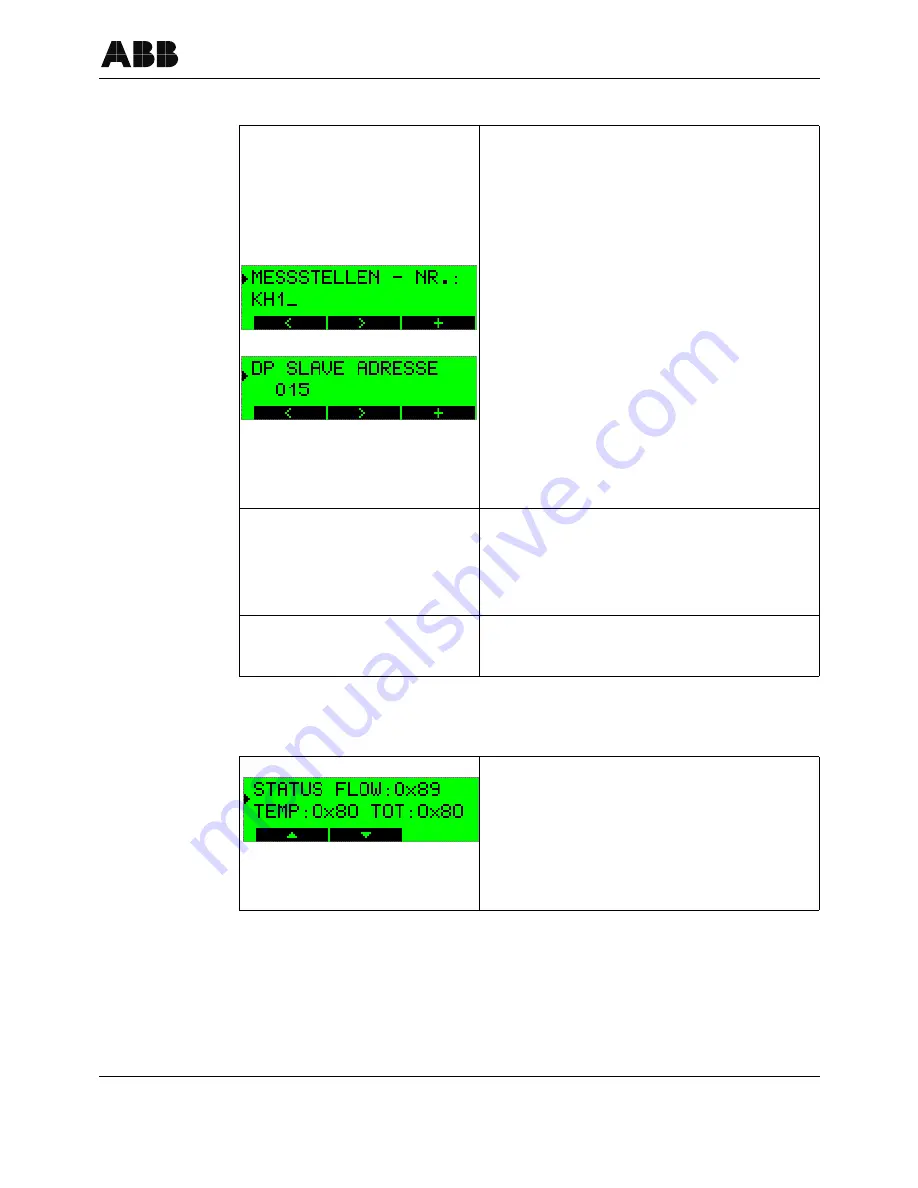

The examples MEASURING POINT NO. and DP SLAVE

ADDRESS are used to demonstrate entering and chan-

ging data. Both entry masks are found in the PARAMETER

MENU that can be accessed by actuating the up/down AR-

ROW buttons from any display mode. The SERVICE or

SPECIALIST mode must have been set in order to make

entries and changes (see section 7.4.3).

After selecting the PARAMETER MENU, open it with the

ENTER button. The display shows MEASURING POINT

NO. and in the second line the set TAG number. With the

ENTER button you switch to change mode (see figure on

the left).

The data is entered by actuating the left/right ARROW but-

tons (cursor position) and the + button (setting the numeric

value or the desired character). To terminate the entry, the

cursor must be positioned to the right behind the entry

field. Only at this cursor position the + button becomes the

ENTER button again and can be used to save the entry

and exit the change mode.

The display switches back to the PARAMETER MENU

where you can make further configuration changes.

To save the entries and changes permanently you must

select the menu item SAVE CONFIG. in the PARAMETER

MENU and confirm with ENTER. If you do not save the

data the changes are lost during a hardware reset or in

case of a power failure.

The menus can only be left via the END..... MENU mask

by using the ENTER button.

In the SERVICE MENU and in different other locations of

the individual menus you can call up the hexadecimal sta-

tus signals of the measuring values FLOW, TEMP, and

TOT. (For explanations see sections 7.1.2.2 and 7.1.2.3)

Furthermore, eight diagnostic signal are available in the

SERVICE MENU, showing information about the device

status. (For explanation

see section 7.1.3 "Acyclic data

communication (DPV1)" on page 27

)