100

5.9.4.

Check the injection pressure

Check once every 500 hours.

The injection pressure should be checked periodically according to the intervals

shown in the maintenance table and adjusted if necessary. This check should be

carried out by our after-sales team!

The efficiency of the engine basically depends on the working condition of the

injector nozzle, so it must be maintained regularly to ensure its proper working.

The driver of the excavator should pay attention to the signs shows the injectors are

not working properly in order to better use the engine.

A. Single or multi-cylinder banging sound; B. Engine overheating; C. Decreased

efficiency; D. Darkened exhaust; E. Increased fuel consumption.

These signs may also be caused by the following reasons, so also do the following

checks first.

A. Poor intake and exhaust valve seals; B. Incorrectly adjusted fuel injectors; C.

Dirty or damaged fuel filters; D. Poor fuel quality; E. Water in the fuel; F. Dirty or

clogged air filter.

5.9.5.

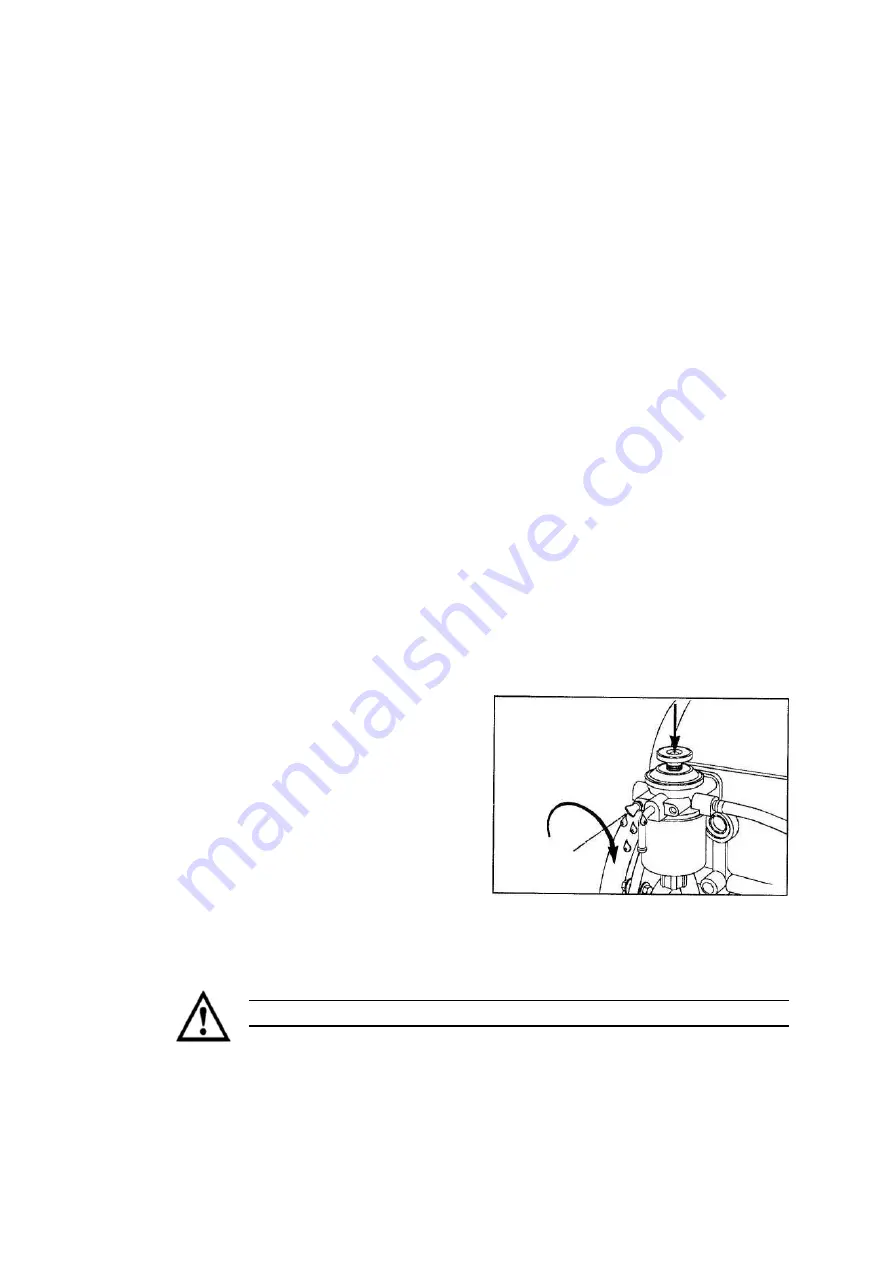

Vent air from fuel circuit

If air enters the fuel circuit after replacing

the fuel filter, disconnecting the fuel line,

cleaning the fuel filter, or by accidentally

emptying the fuel tank, the air should be

removed before restarting the engine.

1)

Open the air vent screw on the fuel

filter holder.

2)

Run the filler pump plug until there is

no air in the fuel flowing out of the vent screw.

3)

Close the air vent screw on the fuel filter holder.

WARNING: The fuel pressure in the high-pressure fuel line is

sufficient to penetrate the skin and may cause serious injury. Gloves