REAR BRAKE

4-61

2. Check:

• Brake master cylinder kit

Damage/scratches/wear

→

Replace.

3. Check:

• Brake fluid reservoir

Cracks/damage

→

Replace.

• Brake fluid reservoir diaphragm

Cracks/damage

→

Replace.

4. Check:

• Brake hose

Cracks/damage/wear

→

Replace.

EAS22730

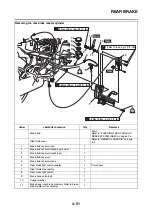

ASSEMBLING THE REAR BRAKE MASTER

CYLINDER

WARNING

EWA13520

• Before installation, all internal brake com-

ponents should be cleaned and lubricated

with clean or new brake fluid.

• Never use solvents on internal brake com-

ponents.

EAS22740

INSTALLING THE REAR BRAKE MASTER

CYLINDER

1. Install:

• Copper washers

• Brake hose (rear brake master cylinder to

brake pipe/middle joint assembly) “1”

• Rear brake hose union bolt “2”

WARNING

EWA1MC1014

Proper brake hose routing is essential to in-

sure safe vehicle operation. Refer to “CABLE

ROUTING” on page 2-47.

NOTICE

ECA14160

When installing the brake hose onto the

brake master cylinder, make sure the brake

pipe touches the projection “a” as shown.

2. Install:

• Rear brake light switch “1”

TIP

Install the rear brake light switch spring as

shown in the illustration.

3. Fill:

• Brake fluid reservoir

(with the specified amount of the specified

brake fluid)

WARNING

EWA13090

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake fluids

may result in a harmful chemical reaction,

leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor lock.

NOTICE

ECA13540

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean up

any spilt brake fluid immediately.

Specified brake fluid

DOT 4

T

R

.

.

Brake hose union bolt

30 Nm (3.0 m·kg, 22 ft·lb)

New

Specified brake fluid

DOT 4

1

2

a

1

Summary of Contents for FJR1300A(D)

Page 1: ...2013 SERVICE MANUAL FJR1300A D 1MC 28197 E0 ...

Page 6: ......

Page 8: ......

Page 70: ...SPECIAL TOOLS 1 61 ...

Page 101: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 30 ...

Page 104: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 33 EAS20410 LUBRICATION DIAGRAMS 5 6 7 1 2 3 4 ...

Page 106: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 35 1 3 2 ...

Page 107: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 36 1 Main axle 2 Drive axle 3 Oil delivery pipe 1 ...

Page 108: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 37 6 5 4 3 2 1 ...

Page 110: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 39 1 2 3 4 5 6 7 8 9 ...

Page 112: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 41 4 5 3 2 1 9 8 6 7 ...

Page 116: ...COOLING SYSTEM DIAGRAMS 2 45 7 1 2 3 4 5 5 8 9 6 8 9 10 11 12 ...

Page 124: ...CABLE ROUTING 2 53 Horn and radiator left side view A B 1 1 2 3 4 5 5 6 C 7 7 8 ...

Page 132: ...CABLE ROUTING 2 61 Rear fender top view 1 2 3 B C A B ...

Page 138: ...CABLE ROUTING 2 67 ...

Page 141: ......

Page 377: ...MIDDLE GEAR 5 76 Middle driven pinion gear shim Thickness mm 0 10 0 15 0 20 0 30 0 40 0 50 ...

Page 428: ...WATER PUMP 6 15 ...

Page 455: ...IGNITION SYSTEM 8 6 ...

Page 461: ...ELECTRIC STARTING SYSTEM 8 12 ...

Page 465: ...CHARGING SYSTEM 8 16 ...

Page 477: ...SIGNALING SYSTEM 8 28 ...

Page 533: ...FUEL INJECTION SYSTEM 8 84 ...

Page 551: ...CRUISE CONTROL SYSTEM 8 102 ...

Page 555: ...FUEL PUMP SYSTEM 8 106 ...

Page 563: ...ACCESSORY BOX SYSTEM 8 114 ...

Page 573: ...IMMOBILIZER SYSTEM 8 124 ...

Page 577: ...ABS ANTI LOCK BRAKE SYSTEM 8 128 ...

Page 616: ...ELECTRICAL COMPONENTS 8 167 7 1 3 2 18 21 20 19 9 11 12 13 14 15 16 17 6 8 4 5 10 ...

Page 658: ......

Page 659: ......

Page 660: ......