5-29

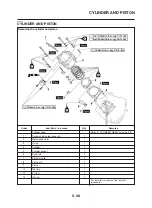

CYLINDER AND PISTON

3. Measure:

• Piston ring end gap

Out of specification

→

Replace the piston ring.

NOTE:

The oil ring expander spacer’s end gap cannot

be measured. If the oil ring rail’s gap is exces-

sive, replace all three piston rings.

Piston ring end gap

Top ring

0.20-0.35 mm

(0.0079-0.0138 in)

<Limit>: 0.60 mm (0.0236 in)

2

nd

ring

0.35-0.50 mm

(0.0138-0.0197 in)

<Limit>: 0.85 mm (0.0335 in)

Oil ring

0.20-0.70 mm

(0.0079-0.0276 in)

EAS00265

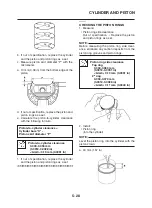

CHECKING THE PISTON PIN

1. Check:

• Piston pin

Blue discoloration/grooves

→

Replace the

piston pin, and then check the lubrication

system.

2. Measure:

• Piston pin outside diameter “a”

Out of specification

→

Replace the piston

pin.

Piston pin outside diameter

22.991-23.000 mm

(0.9052-0.9055 in)

<Limit>: 22.971 mm (0.9044 in)

3. Measure:

• Piston pin bore inside diameter “b”

Out of specification

→

Replace the piston.

Piston pin bore inside diameter

23.004-23.015 mm

(0.9057-0.9061 in)

<Limit>: 23.045 mm (0.9073 in)

4. Calculate:

• Piston-pin-to-piston-pin-bore clearance

Out of specification

→

Replace the piston pin

and piston as a set.

Piston-pin-to-piston clearance

0.004-0.024 mm

(0.0002-0.0009 in)

<Limit>: 0.074 mm (0.0029 in)

Piston-pin-to-piston-pin-bore clearance =

Piston pin bore inside diameter “b” –

Piston pin outside diameter “a”

EAS00267

INSTALLING THE PISTON AND

CYLINDER

1. Install:

• Top ring “1”

• 2

nd

ring “2”

• Oil ring expander “3”

• Lower oil ring rail “4”

• Upper oil ring rail “5”

NOTE:

Be sure to install the piston rings so that the

manufacturer’s marks or numbers face up.

a

Summary of Contents for 2008 Tenere

Page 1: ...SERVICE MANUAL 2008 11D F8197 E0 XT660Z ...

Page 8: ......

Page 24: ......

Page 44: ...2 20 TIGHTENING TORQUES Cylinder head tightening sequence 2 4 3 1 ...

Page 54: ...2 30 COOLING SYSTEM DIAGRAMS 1 2 3 4 5 6 7 9 10 11 12 5 8 11 A ...

Page 57: ...2 33 LUBRICATION DIAGRAMS LUBRICATION DIAGRAMS 1 A A A A B B B A A B 3 2 2 4 1 1 5 5 ...

Page 59: ...2 35 LUBRICATION DIAGRAMS A A A A 3 1 2 3 4 ...

Page 60: ...2 36 LUBRICATION DIAGRAMS 1 Oil delivery pipe 2 2 Oil delivery pipe 1 3 Oil filter 4 Oil pump ...

Page 61: ...2 37 LUBRICATION DIAGRAMS 1 7 2 3 4 5 6 A ...

Page 63: ...2 39 LUBRICATION DIAGRAMS 1 6 5 4 3 2 ...

Page 65: ...2 41 CABLE ROUTING CABLE ROUTING ...

Page 67: ...2 43 CABLE ROUTING ...

Page 69: ...2 45 CABLE ROUTING ...

Page 71: ...2 47 CABLE ROUTING ...

Page 73: ...2 49 CABLE ROUTING ...

Page 75: ...2 51 CABLE ROUTING ...

Page 77: ...2 53 CABLE ROUTING ...

Page 79: ...2 55 CABLE ROUTING ...

Page 81: ...2 57 CABLE ROUTING ...

Page 83: ...2 59 CABLE ROUTING ...

Page 176: ...4 56 FRONT FORK WARNING Make sure the brake hoses are routed prop erly 1 2 3 ...

Page 270: ......

Page 284: ......

Page 301: ...7 17 FUEL INJECTION SYSTEM WIRING DIAGRAM ...

Page 324: ......

Page 327: ...8 1 IGNITION SYSTEM EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 331: ...8 5 ELECTRIC STARTING SYSTEM EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 337: ...8 11 CHARGING SYSTEM EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 338: ...8 12 CHARGING SYSTEM 2 A C magneto 5 Rectifier regulator 7 Battery 8 Main fuse ...

Page 340: ...8 14 CHARGING SYSTEM ...

Page 341: ...8 15 LIGHTING SYSTEM EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 345: ...8 19 SIGNALING SYSTEM EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 351: ...8 25 COOLING SYSTEM EAS00807 COOLING SYSTEM CIRCUIT DIAGRAM ...

Page 354: ...8 28 COOLING SYSTEM ...

Page 355: ...8 29 IMMOBILIZER SYSTEM ET5YU1002 IMMOBILIZER SYSTEM ET5YU1003 CIRCUIT DIAGRAM ...

Page 364: ...8 38 IMMOBILIZER SYSTEM ...

Page 365: ...8 39 ELECTRICAL COMPONENTS EAS27970 ELECTRICAL COMPONENTS ...

Page 367: ...8 41 ELECTRICAL COMPONENTS ...

Page 369: ...8 43 ELECTRICAL COMPONENTS EAS27980 CHECKING THE SWITCHES ...

Page 388: ......

Page 390: ......

Page 396: ...COLOR CODE ...

Page 397: ......

Page 398: ...YAMAHA MOTOR ITALIA S P A ...

Page 399: ...XT660Z 2008 WIRING DIAGRAM ...