4-62

REAR SHOCK ABSORBER ASSEMBLY

EAS23180

HANDLING THE REAR SHOCK ABSORBER

EWA13740

WARNING

This rear shock absorber contains highly

compressed nitrogen gas. Before handling

the rear shock absorber, read and make

sure you understand the following informa-

tion. The manufacturer cannot be held re-

sponsible for property damage or personal

injury that may result from improper han-

dling of the rear shock absorber.

•

Do not tamper or attempt to open the rear

shock absorber.

•

Do not subject the rear shock absorber to

an open flame or any other source of high

heat. High heat can cause an explosion

due to excessive gas pressure.

•

Do not deform or damage the rear shock

absorber in any way. Rear shock absorber

damage will result in poor damping perfor-

mance.

EAS23190

DISPOSING OF A REAR SHOCK

ABSORBER

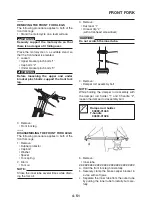

1. Gas pressure must be released before dis-

posing of a rear shock absorber. To release

the gas pressure, drill a 2-3 mm (0.079-

0.118 in) hole through the rear shock ab-

sorber at a point 15-20 mm (0.6-0.8 in) from

its end as shown.

EWA13760

WARNING

Wear eye protection to prevent eye damage

from released gas or metal chips.

EAS23230

REMOVING THE REAR SHOCK

ABSORBER ASSEMBLY

1. Stand the vehicle on a level surface.

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

NOTE:

Place the vehicle on a suitable stand so that

the rear wheel is elevated.

EAS23240

CHECKING THE REAR SHOCK

ABSORBER ASSEMBLY

1. Check:

• Rear shock absorber rod

Bends/damage

→

Replace the rear shock

absorber assembly.

• Rear shock absorber

Gas leaks/oil leaks

→

Replace the rear

shock absorber assembly.

• Spring

Damage/wear

→

Replace the rear shock ab-

sorber assembly.

• Bolts

Bends/damage/wear

→

Replace.

EAS23310

INSTALLING THE REAR SHOCK

ABSORBER ASSEMBLY

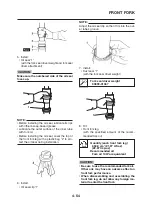

1. Lubricate:

• Flange bolt

• Bolt

Recommended lubricant

Lithium-soap-based grease

2. Install:

• Rear shock absorber assembly “1”

(into the frame support bracket)

• Flange bolt “2”

• Flange nut “3”

3. Tighten:

• Flange nut “3”

Rear shock absorber assembly

nut (frame support bracket)

60 Nm (6.0 m·kg, 44 ft·lb)

Summary of Contents for 2008 Tenere

Page 1: ...SERVICE MANUAL 2008 11D F8197 E0 XT660Z ...

Page 8: ......

Page 24: ......

Page 44: ...2 20 TIGHTENING TORQUES Cylinder head tightening sequence 2 4 3 1 ...

Page 54: ...2 30 COOLING SYSTEM DIAGRAMS 1 2 3 4 5 6 7 9 10 11 12 5 8 11 A ...

Page 57: ...2 33 LUBRICATION DIAGRAMS LUBRICATION DIAGRAMS 1 A A A A B B B A A B 3 2 2 4 1 1 5 5 ...

Page 59: ...2 35 LUBRICATION DIAGRAMS A A A A 3 1 2 3 4 ...

Page 60: ...2 36 LUBRICATION DIAGRAMS 1 Oil delivery pipe 2 2 Oil delivery pipe 1 3 Oil filter 4 Oil pump ...

Page 61: ...2 37 LUBRICATION DIAGRAMS 1 7 2 3 4 5 6 A ...

Page 63: ...2 39 LUBRICATION DIAGRAMS 1 6 5 4 3 2 ...

Page 65: ...2 41 CABLE ROUTING CABLE ROUTING ...

Page 67: ...2 43 CABLE ROUTING ...

Page 69: ...2 45 CABLE ROUTING ...

Page 71: ...2 47 CABLE ROUTING ...

Page 73: ...2 49 CABLE ROUTING ...

Page 75: ...2 51 CABLE ROUTING ...

Page 77: ...2 53 CABLE ROUTING ...

Page 79: ...2 55 CABLE ROUTING ...

Page 81: ...2 57 CABLE ROUTING ...

Page 83: ...2 59 CABLE ROUTING ...

Page 176: ...4 56 FRONT FORK WARNING Make sure the brake hoses are routed prop erly 1 2 3 ...

Page 270: ......

Page 284: ......

Page 301: ...7 17 FUEL INJECTION SYSTEM WIRING DIAGRAM ...

Page 324: ......

Page 327: ...8 1 IGNITION SYSTEM EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 331: ...8 5 ELECTRIC STARTING SYSTEM EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 337: ...8 11 CHARGING SYSTEM EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 338: ...8 12 CHARGING SYSTEM 2 A C magneto 5 Rectifier regulator 7 Battery 8 Main fuse ...

Page 340: ...8 14 CHARGING SYSTEM ...

Page 341: ...8 15 LIGHTING SYSTEM EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 345: ...8 19 SIGNALING SYSTEM EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 351: ...8 25 COOLING SYSTEM EAS00807 COOLING SYSTEM CIRCUIT DIAGRAM ...

Page 354: ...8 28 COOLING SYSTEM ...

Page 355: ...8 29 IMMOBILIZER SYSTEM ET5YU1002 IMMOBILIZER SYSTEM ET5YU1003 CIRCUIT DIAGRAM ...

Page 364: ...8 38 IMMOBILIZER SYSTEM ...

Page 365: ...8 39 ELECTRICAL COMPONENTS EAS27970 ELECTRICAL COMPONENTS ...

Page 367: ...8 41 ELECTRICAL COMPONENTS ...

Page 369: ...8 43 ELECTRICAL COMPONENTS EAS27980 CHECKING THE SWITCHES ...

Page 388: ......

Page 390: ......

Page 396: ...COLOR CODE ...

Page 397: ......

Page 398: ...YAMAHA MOTOR ITALIA S P A ...

Page 399: ...XT660Z 2008 WIRING DIAGRAM ...