4-53

FRONT FORK

EAS00659

ASSEMBLING THE FRONT FORK LEGS

The following procedure applies to both of the

front fork legs.

WARNING

•

Make sure the oil levels in both front fork

legs are equal.

•

Uneven oil levels can result in poor han-

dling and a loss of stability.

NOTE:

When assembling the front fork leg, be sure to

replace the following parts:

– inner tube bushing

– outer tube bushing

– oil seal

– dust seal

– before assembling the front fork leg, make

sure all of the components are clean.

1. Install:

• Inner tube busing

• Outer tube busing

• Oil flow stopper

• Damper rod “1”

• Rebound spring “2”

• Copper washer

WARNING

Always use new copper washer.

CAUTION:

Allow the damper rod assembly to slide

slowly down the inner tube “3” until it pro-

trudes from the bottom of the inner tube.

Be careful not to damage the inner tube.

2. Lubricate:

• Inner tube’s outer surface

New

Recommended lubricant

Fork oil 10W or equivalent

3. Tighten:

• Damper rod assembly bolt “1”

Damper rod assembly bolt

30 Nm (3.0 m·kg, 22 ft·lb)

LOCTITE

®

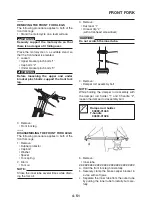

NOTE:

While holding the damper rod assembly with

the damper rod holder “2” and T-handle “3”,

tighten the damper rod assembly bolt.

Damper rod holder

90890-01460

T-handle

90890-01326

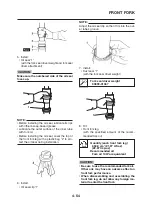

4. Install:

• Outer tube bushing “1”

(with the fork seal driver weight “3” and fork

seal driver attachment “4”

• Washer “2”

New

Fork seal driver weight

90890-01367

Fork seal driver attachment

90890-01374

Summary of Contents for 2008 Tenere

Page 1: ...SERVICE MANUAL 2008 11D F8197 E0 XT660Z ...

Page 8: ......

Page 24: ......

Page 44: ...2 20 TIGHTENING TORQUES Cylinder head tightening sequence 2 4 3 1 ...

Page 54: ...2 30 COOLING SYSTEM DIAGRAMS 1 2 3 4 5 6 7 9 10 11 12 5 8 11 A ...

Page 57: ...2 33 LUBRICATION DIAGRAMS LUBRICATION DIAGRAMS 1 A A A A B B B A A B 3 2 2 4 1 1 5 5 ...

Page 59: ...2 35 LUBRICATION DIAGRAMS A A A A 3 1 2 3 4 ...

Page 60: ...2 36 LUBRICATION DIAGRAMS 1 Oil delivery pipe 2 2 Oil delivery pipe 1 3 Oil filter 4 Oil pump ...

Page 61: ...2 37 LUBRICATION DIAGRAMS 1 7 2 3 4 5 6 A ...

Page 63: ...2 39 LUBRICATION DIAGRAMS 1 6 5 4 3 2 ...

Page 65: ...2 41 CABLE ROUTING CABLE ROUTING ...

Page 67: ...2 43 CABLE ROUTING ...

Page 69: ...2 45 CABLE ROUTING ...

Page 71: ...2 47 CABLE ROUTING ...

Page 73: ...2 49 CABLE ROUTING ...

Page 75: ...2 51 CABLE ROUTING ...

Page 77: ...2 53 CABLE ROUTING ...

Page 79: ...2 55 CABLE ROUTING ...

Page 81: ...2 57 CABLE ROUTING ...

Page 83: ...2 59 CABLE ROUTING ...

Page 176: ...4 56 FRONT FORK WARNING Make sure the brake hoses are routed prop erly 1 2 3 ...

Page 270: ......

Page 284: ......

Page 301: ...7 17 FUEL INJECTION SYSTEM WIRING DIAGRAM ...

Page 324: ......

Page 327: ...8 1 IGNITION SYSTEM EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 331: ...8 5 ELECTRIC STARTING SYSTEM EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 337: ...8 11 CHARGING SYSTEM EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 338: ...8 12 CHARGING SYSTEM 2 A C magneto 5 Rectifier regulator 7 Battery 8 Main fuse ...

Page 340: ...8 14 CHARGING SYSTEM ...

Page 341: ...8 15 LIGHTING SYSTEM EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 345: ...8 19 SIGNALING SYSTEM EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 351: ...8 25 COOLING SYSTEM EAS00807 COOLING SYSTEM CIRCUIT DIAGRAM ...

Page 354: ...8 28 COOLING SYSTEM ...

Page 355: ...8 29 IMMOBILIZER SYSTEM ET5YU1002 IMMOBILIZER SYSTEM ET5YU1003 CIRCUIT DIAGRAM ...

Page 364: ...8 38 IMMOBILIZER SYSTEM ...

Page 365: ...8 39 ELECTRICAL COMPONENTS EAS27970 ELECTRICAL COMPONENTS ...

Page 367: ...8 41 ELECTRICAL COMPONENTS ...

Page 369: ...8 43 ELECTRICAL COMPONENTS EAS27980 CHECKING THE SWITCHES ...

Page 388: ......

Page 390: ......

Page 396: ...COLOR CODE ...

Page 397: ......

Page 398: ...YAMAHA MOTOR ITALIA S P A ...

Page 399: ...XT660Z 2008 WIRING DIAGRAM ...