Publication Number 53719. Issue 3, April 2012

Page 68

SERVICE MANUAL FOR THE 13754 TGX150 INTERNAL RLAN TYPE A/B SC ETM

8.2.6 Paper Movement Faulty

Possible Causes:

(a)

Sync wheel not rotating.

(b)

Sync sensor faulty.

(c)

Sync sensor cable assembly faulty.

Paper movement will normally be sensed by the sync sensor from movement of the sync wheel.

If such movement is not apparent an error message to that effect should be displayed.

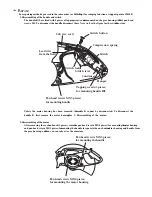

To confirm the serviceability of the sensing components, open the top cover and printer plate

(see Paragraphs 7.2.1 and 7.4.1) and check that the sync wheel is attached to the end of the

paper spigot (see Figure 15) and that the sync wheel rotates when the paper spigot is rotated.

If the wheel is attached to the base of the spigot, then the component to be checked next is the

sensor and its cable assembly (see Figure 32). To check the cable assembly, connect a

multimeter (set to the ohms range) between each of the four pins of the connector at the end

of the sensor cable assembly (normally connected to SKJ (plugged into PLJ on the control

board) and the terminals on the sensor. The meter should indicate continuity in each case if

the wire is serviceable. Any wire of the cable assembly must be renewed if continuity is not

indicated.

To check the serviceability of the sensor, apply power to the ticket machine and ensure that the

sensor connector is plugged into PLJ. With the multimeter set to measure 5V, connect the +ve

terminal of the multimeter to the sensor terminal with the white wire connected and the -ve

terminal of the multimeter to the sensor terminal connected to the black wire. Rotate the paper

spigot. If the sensor is functioning correctly, the reading in the multimeter will vary between

approximately 0 volts and 5 volts as the slots in the sync wheel pass between the two sensor

poles. If this voltage change is not apparent then the sensor must be deemed to be unserviceable

and it must be replaced by a known serviceable item (Paragraph 7.4.6 refers).

If none of these checks suggest a faulty component, then the control board must be faulty and it

must be replaced by a known serviceable item - Paragraph 7.6.5 refers.

8.2.7 Graphic Display Faulty

•

Backlighting, but no graphics displayed

Possible causes:-

(a)

Display cable assembly faulty (PLF, K/bd pcb).

(b)

K/board data cable assembly faulty PLEXT1.

(a)

K/board power cable assembly faulty PLEXT2.

(b)

Control board faulty,

(c)

Graphic display faulty.

The following operations assume that the ticket machine is correctly powered

up and that other functions (i.e. keyboard and printer) are not impaired.

In order to check the continuity of the display to keyboard cable assembly (see

Figure 35), the keyboard and display assembly must be removed - see

Paragraph 7.3.1.