Alpha/Delta (Kinetic Operator) Installation and Maintenance Manual

Revision 1 - MAY 2023

99

RESETTING THE OPEN AND CLOSE LIMITS

Resetting the OPEN and CLOSE Limits

On occasion, the open and close limits may need to be fine-tuned. Resetting the open and close limits

is easily accomplished by accessing the Installer Menu. Examples where resetting the limits is necessary,

include:

• Removing or Replacing the Target Magnet.

•

Setting the LEARN LIMITS display to 1 (erases the open and close target positions from memory).

To re-learn limits, take the following steps:

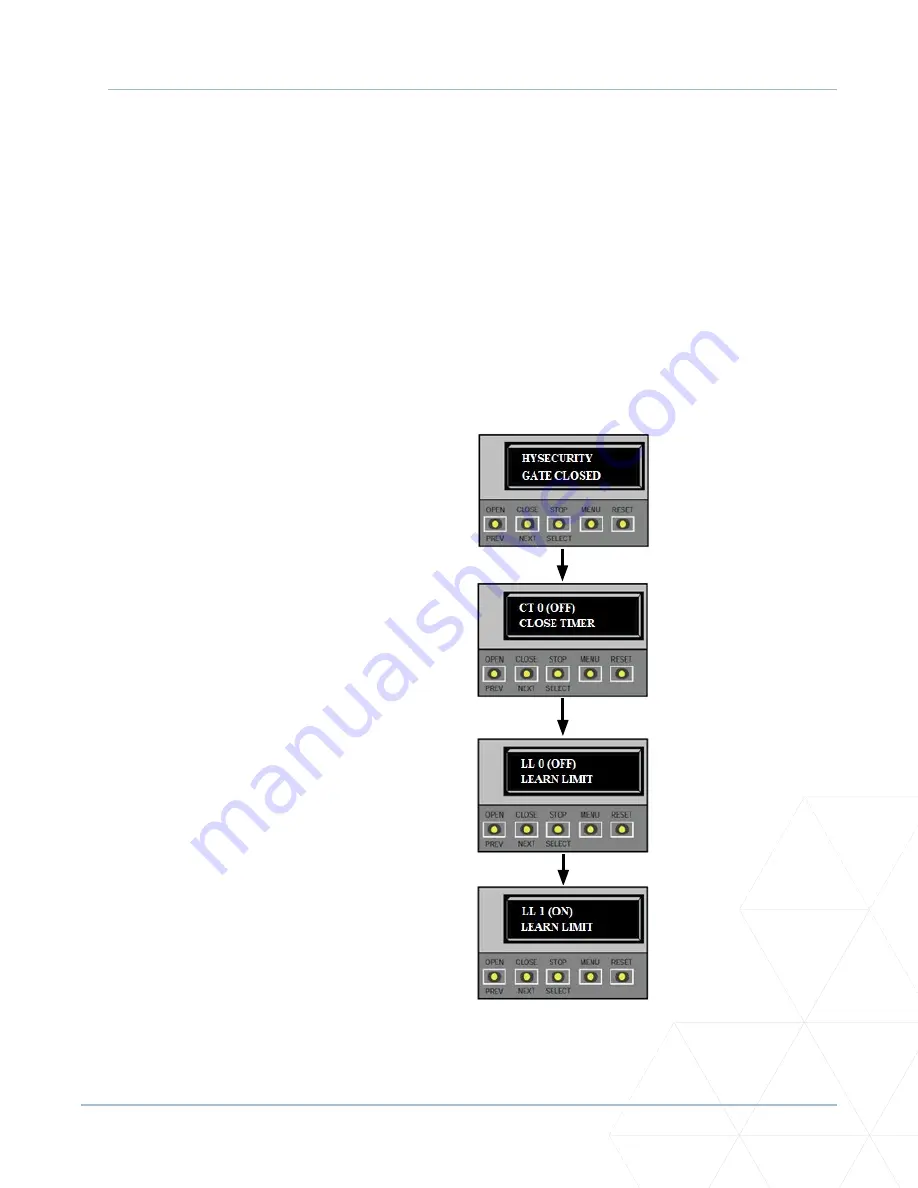

1. At a gate status display, press the MENU

button twice. This accesses the User Menu

and the CLOSE TIMER display appears.

2.

Simultaneously, press the OPEN and RESET

buttons to enter the Installer Menu. Release

the buttons and the LEARN LIMITS display

appears. It is the first item in the Installer

Menu.

3.

Press SELECT, and then NEXT to change the

setting to 1. Press SELECT again. LEARN OPEN

flashes on the display indicating that operator

is ready to relearn the open limit.

4. Hold the OPEN button until the gate reaches

the desired open limit. Release the OPEN

button. (Note that if you go too far, you can

press CLOSE to reverse direction.)

5.

Press STOP twice to preserve the open stop

location. LEARN CLOSE appears on the display.

6.

Hold the CLOSE button until the gate slides to

full close. Release the CLOSE button. (Note

that if you go too far, you can press OPEN to

reverse direction.)

7.

Press STOP twice. The full close stop is

retained in memory. For more information,

refer to

“Establishing the OPEN and CLOSE

.

8. An ALERT 15 message appears on the display.

To clear the alert, perform a full cycle so

the software recognizes the target. Press

OPEN, and then CLOSE. The gate will stop

automatically on the close cycle when it

reaches the programmed limit. As the target

magnet passes the sensor, the operator beeps

and the ALERT 15 message is cleared.

1. Start at a gate status

display.

2. Access the User Menu

by pressing the MENU

button twice.

3. Access the Installer

Menu by simultaneously

pressing the OPEN and

RESET buttons.

4. Press SELECT and

change the setting to 1

using the NEXT button.

Press SELECT again. The

LEARN OPEN display

appears. Refer to steps 4

through 8.

Summary of Contents for ALPHA

Page 167: ...Figure 47 Schematic for Kinetic DC 15 Kinetic 1 and Kinetic DC 10F Kinetic 2 Operator s...

Page 168: ......

Page 170: ......

Page 180: ......