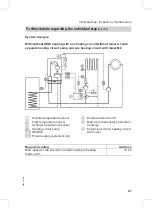

Rated output

kW

12.9/19.3

16.1/23.5

(see page 18)

!

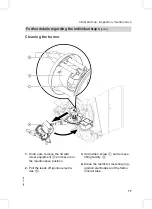

Please note

An incorrectly adjusted nozzle gap "a" can result in irregular operation of

the burner and even a fault shutdown.

Always

maintain the stated dimension and check in accordance with the

details on page 18.

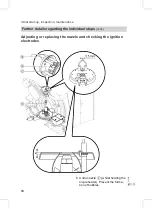

Adjusting the oil pressure and checking the vacuum

Oil pump; make: Danfoss,

type BFP 52

1.

Insert the pressure gauge (range

0 - 25 bar) into test port "P"

A

and

the vacuum gauge (range 0 -

1 bar) into test port "V"

B

.

Note

Seal the pressure and vacuum

gauges only with copper or alumi-

nium gaskets or with O-rings.

Never use tape to seal these

joints.

2.

Start the boiler.

3.

Press

K

and

d

simultaneously

for approx. 2 s.

"Relay test" is shown in the dis-

play.

4.

Select burner stage 1 with

a

and

b

.

"Burner st 1 ON" is shown on the

display.

5.

Where vacuum measures higher

than 0.35 bar, check the filter for

contamination or check the pipe

route.

Further details regarding the individual steps

(cont.)

13

Initial start-up, inspection, maintenance

5692

536

GB

Summary of Contents for Vitoplus 300

Page 103: ...Parts lists cont 103 Parts lists 5692 536 GB ...

Page 104: ...Parts lists cont 104 Parts lists 5692 536 GB ...

Page 105: ...Parts lists cont 105 Parts lists 5692 536 GB ...

Page 106: ...Parts lists cont 106 Parts lists 5692 536 GB ...

Page 107: ...Parts lists cont 107 Parts lists 5692 536 GB ...

Page 119: ...119 5692 536 GB ...