8-5

Valco Cincinnati, Inc.

Section 8 - Glue Pattern Edit Menu

MC032 - MCP-25 Control

15

15

15

15

15 F5

F5

F5

F5

F5

Pressing F5 (>>>) displays the information for glue patterns 3,4,

and 5.

16

16

16

16

16 MODE

MODE

MODE

MODE

MODE

Moving the cursor onto the word “MODE” and then pressing the

“ENTER” button displays the mode-selection screen (see

“Selecting a Mode” in this section”).

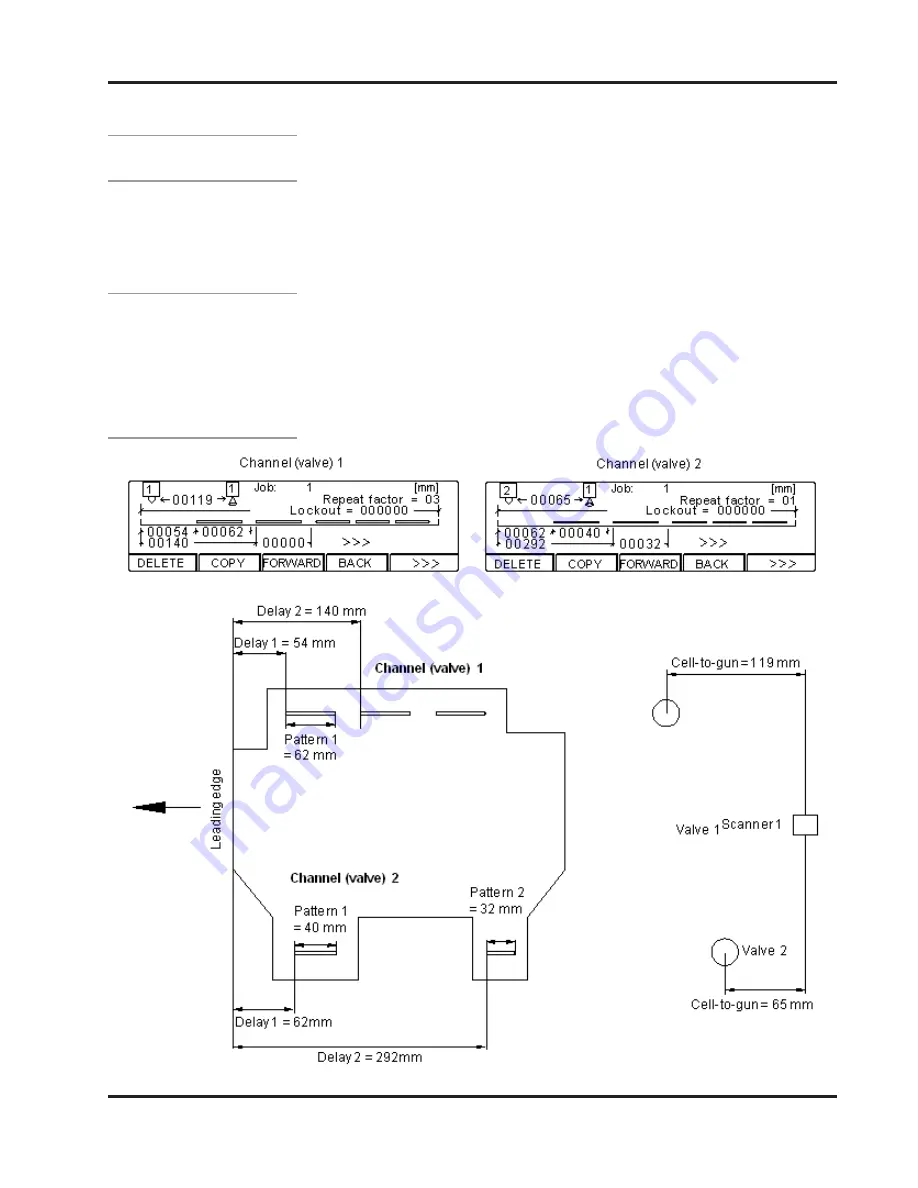

Glue-Pattern-Edit Parameters -

Continued

Glue-Pattern-

Example

(Standard

Mode)