VIII.

REPAIRING THE WHEEL

S

Having removed the wheel and prior to repairs, check:

- wear of tires and their possible damage;

- cracks and dents of the wheel rim;

- wear on the brake drum surface;

- wear in the taper roller bearings and

spacers;

- radial and side run-out of the rim and tire;

- presence and uniform tightening of all the wheel spokes. Check condition of the bearings in

wheel hubs not by rotating and rocking the wheel on the axle, but, on the contrary, by rotating

the tightened axle and rocking it in the wheel, because •due to the considerable weight of the

wheel the overtightening of the bearings may be unnoticed. The axle should rotate freely,

without noticeable run-out, seizing, clicks, etc.

Radial and side run-out in a running wheel may be tolerated within 1.5 mm for the wheel rim and

within 3 mm for the tire. Repair the wheels if any defects are revealed.

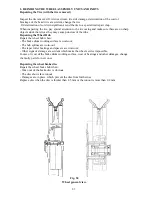

1. DISMANTLING AND REASSEMBLING THE WHEEL

Demounting and Remounting the Tire

(With the wheel removed)

Required tools and fixtures are:

- Tire irons (2 pieces);

- Hand-operated tire pump;

- Tire gauge for measuring the pressure in tires.

To remove the tire from the wheel:

- Turn off the valve cap, turn off the slide valve, and push the valve inside the tire;

- Lay the wheel with the brake drum down and press off the tire sides so as to separate them

from the rim shoulders;

- At a distance of approximately

1/4

on the wheel circumference from the tire valve, press the tire

bead into the center of rim well and use tire irons, inserting them from the opposite side of the

rim to catch the tire bead and twist it outside through the rim shoulder. Smear the tire iron ends

with liquid soap to facilitate inserting;

- By moving both irons along the rim and pressing the tire beads into the rim well from the

opposite, side, gradually remove the whole tire bead. When removing, make sure that the irons

do not pinch the inner tube. Do not exert too much force as otherwise the bead wire may be

damaged; see that the tire bead on the opposite side (not yet removed) lies in the center of the

rim well and the inner tube is not seized;

- Once one side of the tire bead is freed, pull it off preferably near the tire valve and take the

inner tube out.

To remove the tire off the wheel rim, holding the wheel in the vertical position, insert the tire

iron from the side of the tire bead not yet removed, catch the tire bead with the iron end and twist

it outside (see that the opposite side of the not-removed tire bead also enters the rim well). By

moving the irons along the wheel rim remove the tire from the rim.

After demounting, inspect the tire and inner tube and check for punctures, other possible

damage, sharp or foreign matters on the inner surface of the tire. If necessary, repair the tire and

the inner tube, or replace them.

To remount the tire and the inner tube, proceed as follows:

- Powder the inside of the tire casing with talcum;

- Fit on the rim flap, matching its hole for nipple with those in the rim well. Make sure that the

flap covers entirely all the nipple heads, while no spokes are protruding from the nipple heads;

81

Summary of Contents for 750cc Series

Page 1: ...Repair Manual 750cc All Models www imz ural com ...

Page 2: ......

Page 71: ...1 2 3 4 5 6 7 8 Fig 66 Final drive 71 ...

Page 98: ...Fig 11 iring Diagram 9 W 98 ...