Oil lines.

In the course of total of partial dismantling of the engine, especially when

reassembling, pay attention to correct mating of the oil ducts and clean them properly. Also see

that the gaskets in the joint planes do not overlap the holes, the joints are tight with no leaks of

oil.

In the event of total dismantling of the engine, check to reveal porous spots and pitting in the oil

line of the engine crankcase, and to this end:

- Close with rubber plugs the holes through which oil is fed to the left-hand cylinder, to the

housings of front and rear bearings, and to the hole in the duct on the pump fastening plane; use

a hose to feed water under a pressure of 1 m w. g.;

- Inspect all the oil lines, checking them for leaks of water;

- If leakage is revealed, remedy by caulking the leaky points. Having completed the tightness

check, remove the plugs; water should flow out of the holes easily, thus pointing to the clean-

liness of ducts.

Inspect the oil filter. In case of damage, heavy contamination or the expiry of service life, change

the filter.

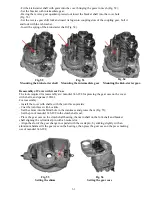

Repairing the Engine Crankcase and Covers

In the course of an overhaul or partial dismantling of the engine, check the condition of the

crankcase and the engine covers. When inspecting pay attention to:

- Cracks or other damages;

- Dents, burrs, etc. from the gaskets formerly installed,

grit

on the planes of joints;

- Worn-out spots

on fitting planes (especially in the points where the bearing is fitted);

- Loose studs, stripped thread;

- Untightness of flaring or pressing-in of

pipes;

- Wear of the camshaft rear bearing (bushing);

- Scores of the oil pump drive bushing;

- Wear and scores in the holes for the breather on the gearbox cover.

Eliminate the detected troubles if possible or change the defective parts. Also check the

condition of removed bearings and change them, if worn-out.

Repairing the Clutch Mechanism

The required tools and fixtures are blades for checking the balancing of the flywheel.

Having dismantled the clutch, wash its parts and check:

- Condition; of the working surfaces of the clutch plates (scores, dents);

- Condition of splines in the hub of the driven plates;

- Riveting of clutch driven disk hubs;

- Wear of parts of the clutch;

- Resilience of springs.

- Condition of toothed crown of the flywheel. When cracks or broken teeth, or excessive wear-

out are found replace the crown.

If scores or dents on the driven plates, or excessive wear-out are evident, change the clutch

plates. If riveting shows loosed jump the week point.

The unloaded clutch springs are 43 mm long. The clutch springs should be of the same color

marking. The springs are marked out, at the Manufacturing Works. When compressed up to 21

mm, the color marking on the spring ends should correspond to the following loads, N:

Gray ………..170...186

Black………..157...170

55

Summary of Contents for 750cc Series

Page 1: ...Repair Manual 750cc All Models www imz ural com ...

Page 2: ......

Page 71: ...1 2 3 4 5 6 7 8 Fig 66 Final drive 71 ...

Page 98: ...Fig 11 iring Diagram 9 W 98 ...