33

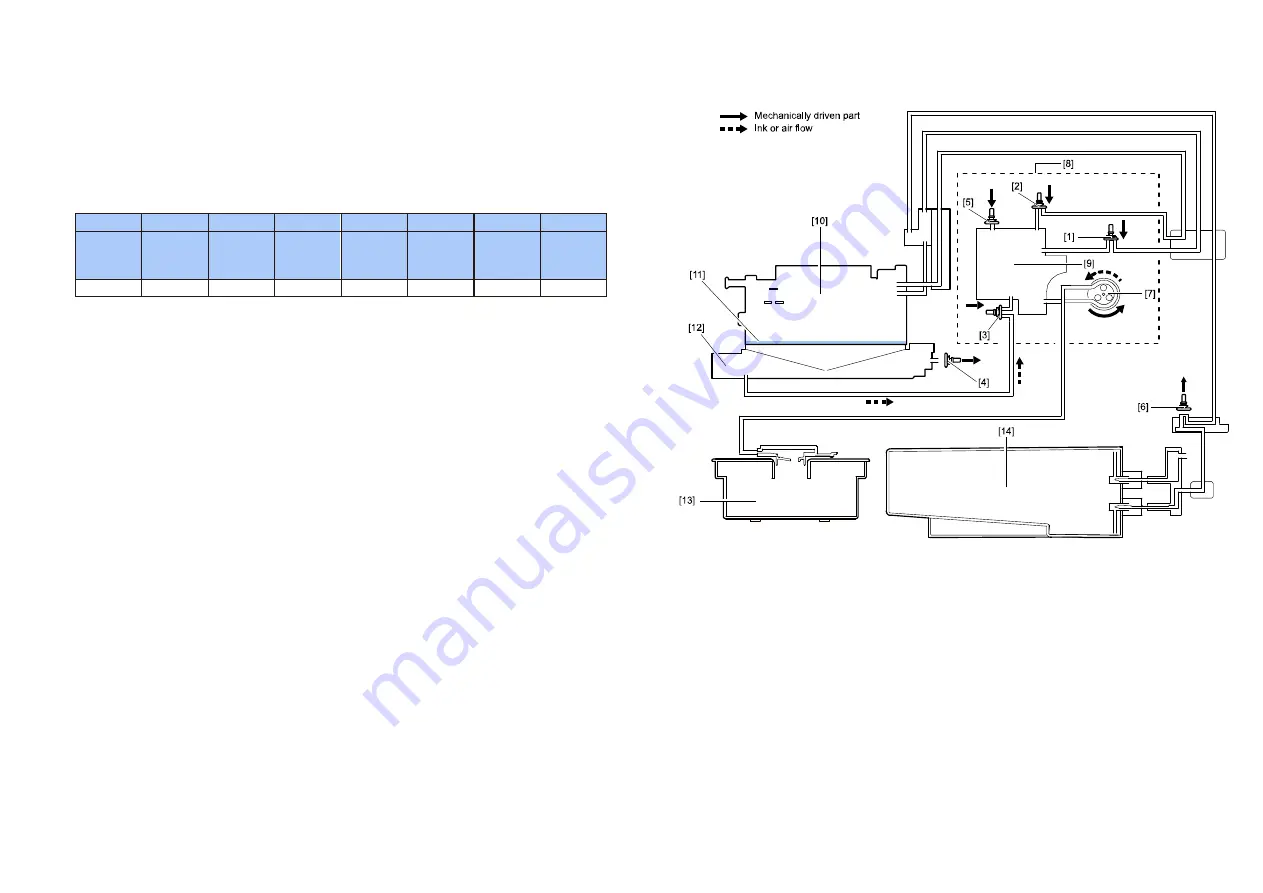

Ink loading: Collection of shipping ink (1)/Reduction of Pressure in Buffer

All valves other than Wipe Valve are closed with Printhead capped, and Suction Pump is driven to

reduce the pressure in Buffer.

Open/closed states of valves, the operation state of Suction Pump, and the capping state of Printhead

are shown below.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

-

Bubble

Removing

Valve

Ink

Supply

Valve

Suction

Valve

Air

Release

Valve

Buffer

Valve

Wipe

Valve

Suction

Pump

Between

Printhed

and Cap

Open

Closed

Closed

Open

Closed

Open

Driven

Sealed

A schematic diagram of ink passages is shown below.

[8]

Pump Unit

[12]

Purge Unit (capping position)

[9]

Buffer

[13]

Maintenance Cartridge

[10]

Printhead

[14]

Ink Tank

[11]

shipping ink

Summary of Contents for CPX4P Series

Page 1: ...CPX4P Service Manual COLOR INKJET LABEL PRINTER ...

Page 7: ...3 ...

Page 79: ...75 17 Remove Ink Tank Holder Unit ...

Page 228: ...224 General Circuit Diagram General Circuit Diagram 1 3 ...

Page 229: ...225 General Circuit Diagram 2 3 ...

Page 230: ...226 General Circuit Diagram 3 3 ...

Page 231: ...227 Update History Date Content Editor 2018 10 09 Add Flushing cleaning sections Camille ...