19

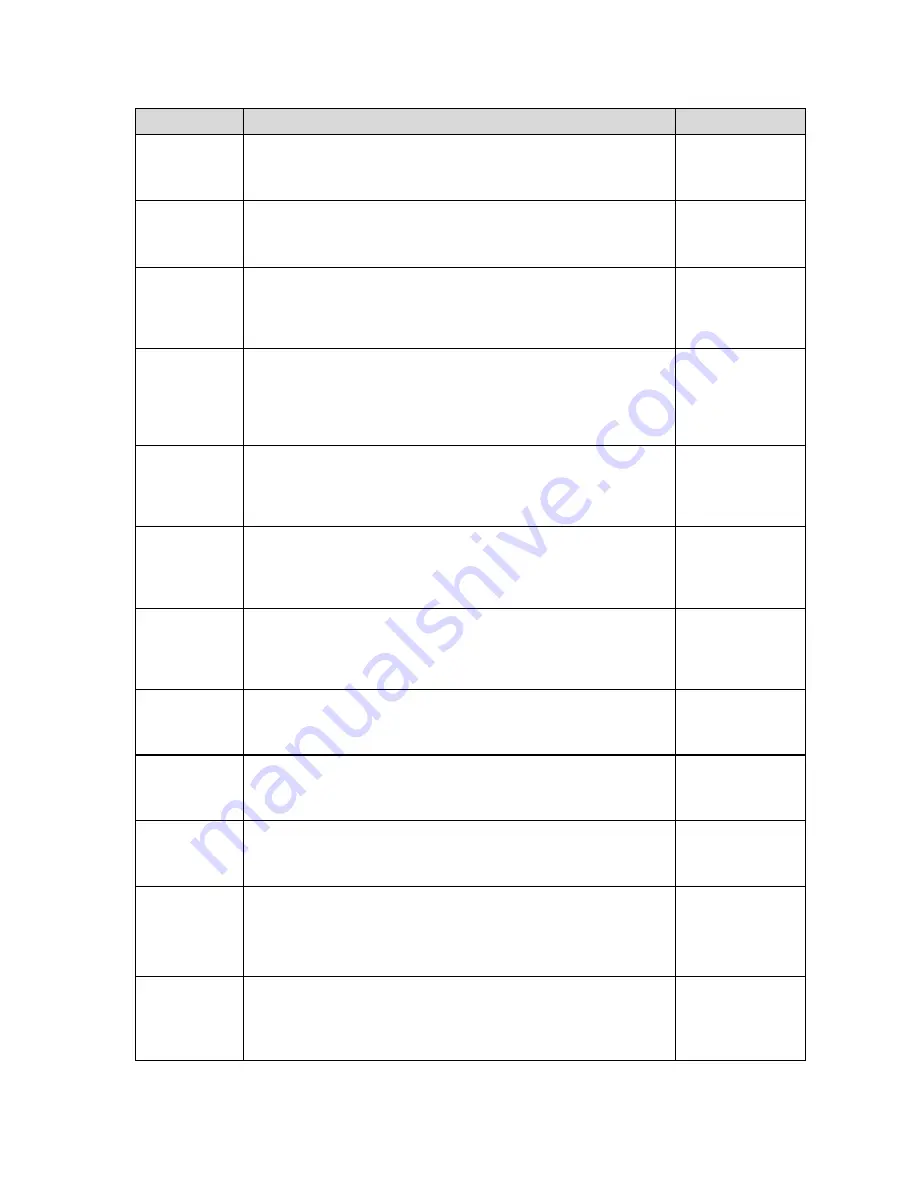

CODE/NAME

DESCRIPTION

SELECTION LIST

A1-8

Set ID Number

Allows you to key-in the ID number. Pressing the

ZERO

key to scroll

down one level begins the sequence.

Key-in

0 to 999999

123456

A1-9

Line Feeds

Allows you to key-in the number of line feeds. Pressing the

ZERO

key

to scroll down one level begins the sequence.

Key-in

0 to 99

8

A1-10

Auto Power Off

Allows you to configure the automatic power off time for the TI-700K

digital indicator. Expressed in minutes of inactivity (keys and weighing

platform). Pressing the

ZERO

key to scroll down one level begins the

sequence.

Key-in

0 to 30

0

(always on)

A1-11

Backlight

Behavior

Allows you to configure the behavior of the LCD backlight for the

TI-700K digital indicator.

"oFF" = Always off

"on" = Always on

“AUto” = Automatic operation

oFF

on

AUto

A1-12-1

Backlight

Color - Normal

Selects the color of the LCD (liquid crystal display) in normal operating

mode.

“1” = Green, “2” = Blue, “3” = R + G + B,

“4” = R + G, “5” = R + B, “6” = G + B

1

2

3 4

5 6

A1-12-2

Backlight

Color - Hold

Selects the color of the LCD (liquid crystal display) when the weight is

locked onto the screen in Hold mode.

“1” = Green, “2” = Blue, “3” = R + G + B,

“4” = R + G, “5” = R + B, “6” = G + B

1

2

3

4

5 6

A1-13

Handshaking

Selects function of the hardware handshaking. (NOTE: Receive pin is

used for handshaking).

"0" = Disabled

"1" = Enabled

0

1

A1-18

Date & Time

Print

Selects function of the printed date and time.

"0" = Disabled

"1" = Enabled

0

1

A1-20

Set System

Time & Date

Allows you to set the system time and date. Pressing the

ZERO

key to

scroll down one level begins the sequence.

Press

ZERO

key

to begin sequence

A1-23

Audible Key

Feedback

Selects function of the audible key feedback (beeper).

"0" = Disabled

"1" = Enabled

0

1

A1-24

Diagnostics

Used to access the listed test functions (one at a time). Pressing the

ZERO

key begins the sequence.

"A1-24-1" = Display segment test, "A1-24-2" = A/D converter test,

“A1-24-5” = Serial Port test (both), “A1-24-6” = Keyboard test

Press

ZERO

key

to begin sequence

A1-25

Output Logic

Use this menu to assign the active logic level to each of the optional

digital output terminals (

OUT1 thru OUT3).

"0" = Low logic, "1" =High logic

0

1