TOSHIBA

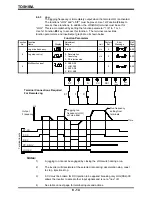

DC INJECTION START FREQUENCY - Specifies the frequency at which DC injection

is applied to a motor during a decelerating stop. Used for precise positioning (inching)

of the motor driven equipment.

DC INJECTION VOLTAGE - Specifies the percent of voltage applied during the

DC injection.

DC INJECTION TIME - Specifies the length of time the DC voltage applied.

SEE SECTION 5.10.

FH

8.7

Operating Functions - Descriptions and Examples (Cont'd)

SECOND FUNCTIONS

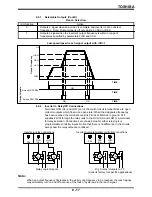

START-UP FREQUENCY - Sets the frequency at which the inverter will begin operating.

In the panel control setting mode the frequency display will change as the "up"

and

"down" keys are pressed. However, an actual output does not occur until the start-

up frequency is reached. In the terminal input mode the display will remain at zero until

the start-up frequency is reached. This function, along with the voltage boost function,

enables the user to obtain an optimum voltage boost level. See figures below.

0

100%

F-St

F-St

0

30%

100%

8 - 26

(Start frequency F-St can be set @ 0 to 10Hz)

Start-Up Frequency

Start-Up Frequency with Voltage Boost

Stop

Start

0

Frun + Fhys

Frun

Frun - Fhys

0%

100%

0

FMAX

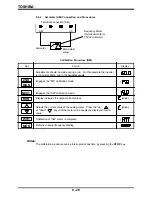

2ND

2ND

1

V/F

Output Frequency

Voltage

boost

Maximum

frequency

% Frequency

Output voltage

Frequency

Frequency setting signal

Output frequency

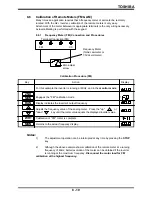

RUN FREQUENCY - Selects a frequency to initiate inverter run/stop control.

RUN FREQUENCY HYSTERESIS - Used to offset inverter run frequency.

When the frequency reference signal reaches the Frun + Fhys point, the drive will ramp

the motor to that speed. The inverter will continue to follow the reference signal until it

falls below the Frun - Fhys at which time the drive will ramp the motor to a stop. See

figure below.

Reference Signal

Hz

Summary of Contents for TOSVERT-130G2+

Page 112: ...TOSHIBA 10 6 Schematics 10 17 ...