4. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

EO18-33012B

4.15 RIBBON SAVING MODULE (B-9904-R2-QM-R)

4-100

1. Follow all manual instructions. Failure to do so could create safety hazards such as fire or

electrocution.

•

Manual instructions must be followed when installing option kits or adding cables to avoid

system failures and to insure proper performance and operation.

•

Failure to follow manual instructions or any unauthorized modifications, substitution or

change to this product will void the limited product warranty.

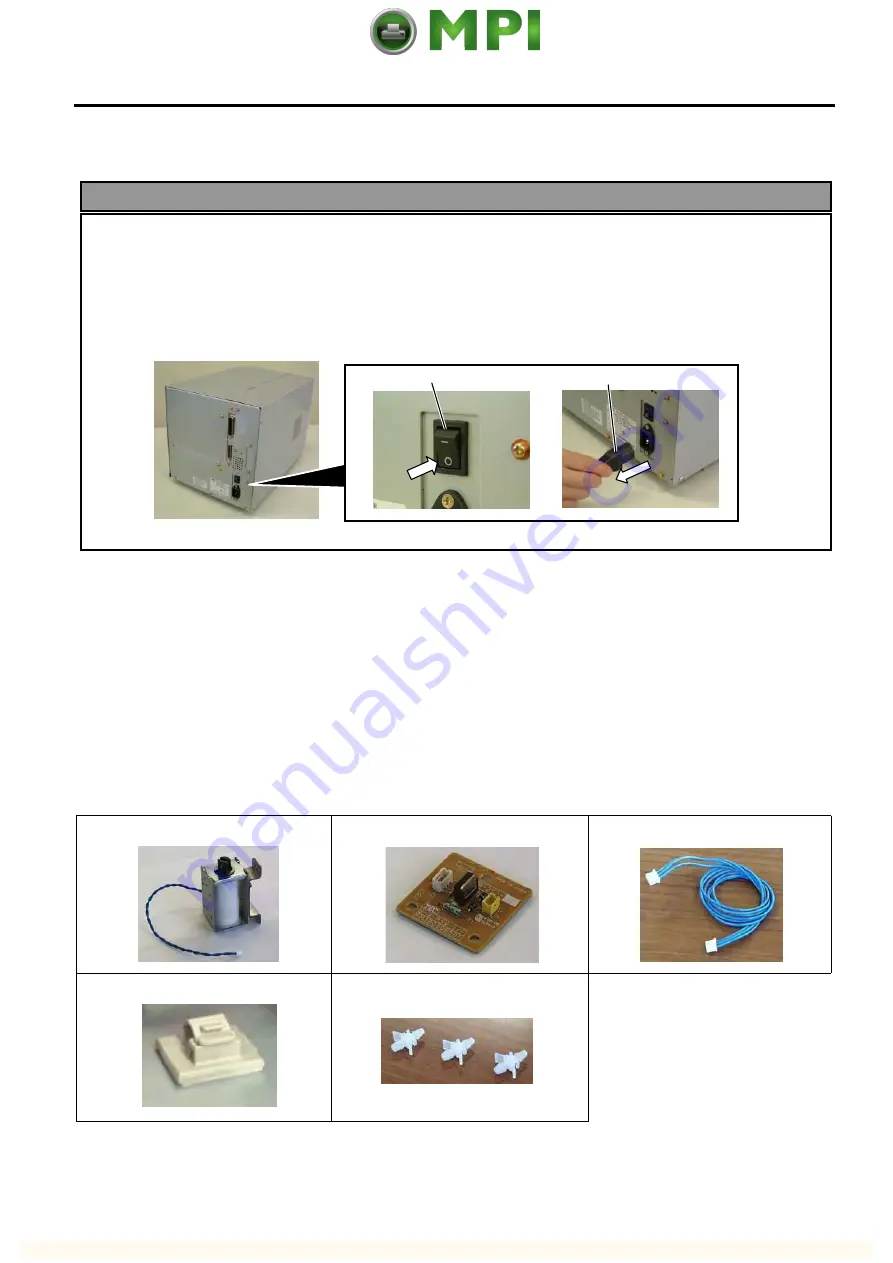

2. Turn the power OFF and disconnect the power cord before installing the ribbon saving module.

3. Be careful not to pinch your fingers or hands with the covers.

4.15 RIBBON SAVING MODULE (B-9904-R2-QM-R)

NOTE: The B-9904-R2-QM Ribbon Saving Module is available only with Firmware V1.2A or later. Please

be careful that the earlier firmware version does not support it.

4.15.1 Applicable Model

This optional device is the ribbon saving module, which is intended for the following models:

B-SX4T-QM-R Series

4.15.2 Packing List

All the following parts are supplied with the kit. Make sure you have all items shown below.

Solenoid (1 pc.)

RSV PC Board (1 pc.)

Solenoid Harness (1 pc.)

Cable Clamp (1 pc.)

Locking Support (3 pcs.)

•

Installation Manual (1 copy)

•

SM-4x8 Screw (2 pcs.)

WARNING!

Power Switch

Power Cord