57

T500 9015504 01-2018

TROUBLESHOOTING

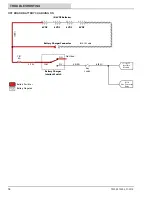

BATTERIES FAIL TO CHARGE / REDUCED RUN

TIME (ONBOARD CHARGER)

Step

Action

Value(s)

Yes

No

1

• Key ON

• Is there a fl ashing BDI fault or LCD Pro-Panel (option) fault

code present?

See FAULTS

in TROUBLE-

SHOOTING

section of this

manual

Proceed to

STEP 2

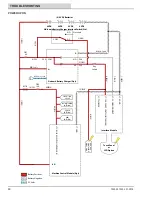

2

• Key OFF

• Check AC power supply

• Is the rated AC supply voltage present?

Proceed to

STEP 3

Check AC

supply circuit

protection

3

• See BATTERY CHARGER SETTINGS in MAINTENANCE

section of this manual and confi rm proper charger settings

• Is the onboard charger set properly?

Proceed to

STEP 4

Reprogram

battery char-

ger

4

• Key OFF

• Inspect battery and charger cables for damage / corrosion /

contamination / terminal problems

• Do any of the above conditions exist?

Repair or replace

battery / battery

charger cables

Proceed to

STEP 5

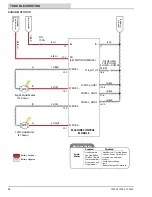

5

• Proceed to STEP 6 for machines equipped with sealed or

AGM batteries

• Key OFF

• Disconnect batteries

• Check water level in all battery cells

• Are the lead plates submerged?

Proceed to

STEP 6

Add distilled

water as nec-

essary until

lead plates are

covered

6

• Key OFF

• Use a hydrometer or refractometer to test specifi c gravity of

each cell (Lead-Acid)

• Are all battery cells within 0.050 (50 points) specifi c gravity

of each other?

Replace battery

charger

Replace bat-

tery charger or

batteries

Terms:

AC = Alternating Current

AGM = Absorbed Glass Mat

Specifi c Gravity = Relative density of a substance

compared to water (1.000 specifi c gravity)

Summary of Contents for t500

Page 5: ...5 T500 9015504 01 2018 CONTENTS ...

Page 55: ...55 T500 9015504 01 2018 TROUBLESHOOTING ...

Page 89: ...89 T500 9015504 01 2018 SERVICE 9 Cycle the key switch to save selections ...

Page 111: ...111 T500 9015504 01 2018 SERVICE ...

Page 117: ...117 T500 9015504 01 2018 SERVICE ...

Page 146: ...146 T500 9015504 01 2018 SERVICE ...