2-12

EM18-33017

2. MAJOR UNIT REPLACEMENT

NOTE:

The above values of the cutter life are obtained on condition that the periodically maintained

cutter is used with TOSHIBA TEC-approved supplies by the proper method described in the

manuals.

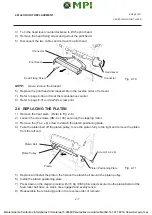

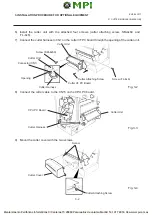

8.

Confirm each part adjustment. Make any necessary adjustments.

9.

Conduct the following tests and make sure that there is no problem.

1)

Print test with TOSHIBA TEC-specified media and ribbon. (Print tone, print head position, etc.)

2)

Paper skew

3)

Print start position adjustment (Horizontal: Media position, Vertical: Sensor adjustment/

Adjustment by issuing commands)

4)

Communication test

5)

Abnorma noise

6)

Confirm that there are not any other errors.

10. Mount the printer cover.

11. Clean the outside of the printer.

12. Fill out a report form. Hand it to the manager and obtain a signature.

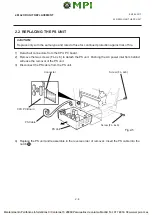

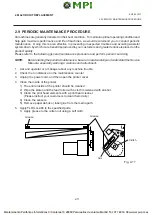

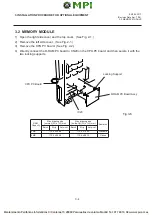

2.9 PERIODIC MAINTENANCE PROCEDURE

No.

1

2

3

4

Part Name

Ribbon Motor

Cutter Unit (Option)

Platen

Feed Rooler

Part No.

FMBB0030501

FMBB0030502

GFM-0065001

FMBC0045501

FMBC0044601

Standard Interval of

Replacement

730 Km

1,000,000 cuts

50 Km

50 Km

6.

Confirm that the problem occurs as reported, and then take corrective action.

7.

Replace the following parts periodically, if necessary. The following table shows approximate

product life for each part.