2-11

EM18-33017

2. MAJOR UNIT REPLACEMENT

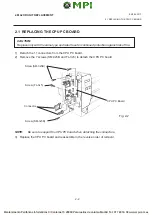

2.9 PERIODIC MAINTENANCE PROCEDURE

2.9 PERIODIC MAINTENANCE PROCEDURE

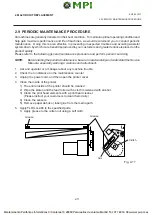

All machines are generally delivered in their best condition. To maintain optimal operating condition and

help gain maximum performance and life of machines, we would recommend you to conduct periodic

maintenance. Doing this is also effective in preventing unexpected troubles and avoiding wasteful

system down, by which more benefit is produced to your customers and greater reliance is placed on the

product quality.

Please refer to the following general maintenance procedure and perform periodic servicing.

NOTE:

Before starting the periodic maintenance, be sure to read carefully and understand the Service

Manuals, especially warnings, cautions and adjustment.

1.

Ask and operator or a manager about any machine trouble.

2.

Check the run distance on the maintenance counter.

3.

Unplug the power cord, and then open the printer cover.

4.

Clean the inside of the printer.

1) The entire inside of the printer should be cleaned.

2) Wipe the platen and the feed roller with a cloth moistened with alcohol.

3) Clean the print head elements with a print head cleaner.

(Please instruct your customers to clean them daily.)

4) Clean the sensors.

5) Remove paper debris or label glue from the media path.

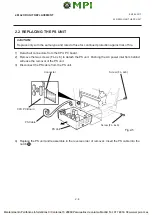

5.

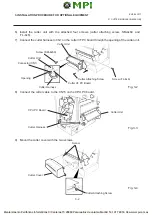

Apply FLOIL G-488 to the specified parts.

1) Apply grease to the cutter unit using a soft cloth.

Grease

Grease

Clutch

Arm

Fig. 2-17