3-3

EM18-33017

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

s

t

r

a

P

d

e

v

o

m

e

R

t

i

n

U

/

y

t

'

Q

s

t

r

a

P

d

e

v

o

m

e

R

t

i

n

U

/

y

t

'

Q

e

t

a

l

p

t

n

o

r

F

1

)

6

x

4

-

L

F

(

w

e

r

c

S

3

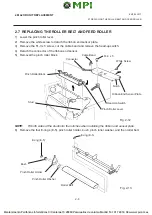

3.1 CUTTER MODULE (B-4208-QM)

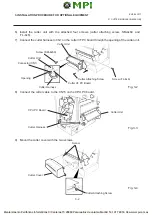

10) Mount the operation panel and the left side cover on the printer.

11) Close the top and right covers.

12) After reassembly is complete, perform a test print to confirm that the cutter works properly. If the print

start position becomes misalign when media is fed in the reverse direction, fine adjust the back feed

value using the Back Feed Fine Adjustment procedure in diag. mode.

NOTES: 1.

If the top edge of label winds onto the platen in cut issue, set DIP SW. 1-5 to ON.

(Refer to the Owner’s Manual.)

2.

Retain the parts that are removed during installation of the cutter unit. They will be

required when the printer is modified to a standard type.

■

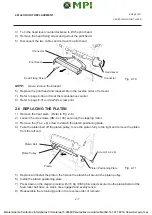

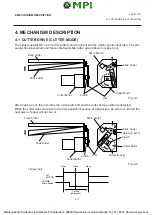

Adjusting the Cutter Guide Plates

After replacing the cutter unit the following adjustment procedure should be employed to prevent

paper jams.

1.

Attach the cutter guide plate A with two SM-4 x 6C screw so that the fixed cutter is positioned

0.1 mm to 0.4 mm above the bottom of the cutter guide plate A.

2.

Attach the cutter guide plate B with two FL-4 x 8 screws so that there is a clearance of 0.5 mm

between the cutter guide plate A and cutter guide plate B using a clearance gauge.

Fixed Cutter

Screw

(SM-4 x 6)

Cutter Guide Plate B

Cutter Guide Plate A

Screw

(FL-4 x 8)

Fig. 3-5

0.1 ~ 0.4 mm

0.5 mm