6-50

EM18-33017

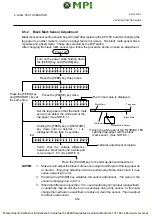

6. DIAG. TEST OPERATION

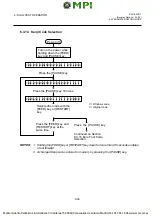

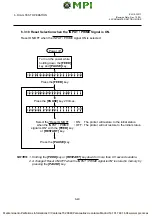

Power off

Turn on the power while holding down

the [FEED] key and [PAUSE] key.

< 1

D I A G N O S T I C

V 1 . O A

>

< 4

S E N S O R

A D J U S T M E N T

>

[ R

F L E C T I V E ]

2 . 8 V

E

[ R

F L E C T I V E ]

3 . 8 V *

E

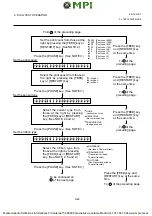

Press the [FEED] key three times.

Set the tag paper so that the black mark

sensor can detect the white part of the

tag paper. (See NOTE 1.)

The former value is displayed.

Holding the [FEED] key or [RESTART]

key down until an asterisk ( * ) is

displayed. (More than 3 seconds.)

Verify that the voltage difference

between a black mark and a white part

is more than 1.5 V. (See NOTE 3)

Indicates adjustment complete.

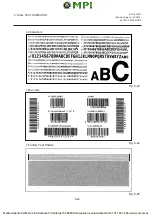

Ex)

Press the [PAUSE] key twice.

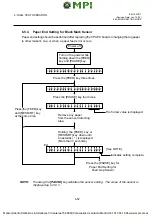

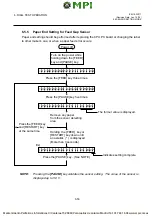

Press the [PAUSE] key for Feed Gap Sensor Adjustment.

Align the white part of the TOSHIBA TEC

specified tag paper with the black

mark sensor. (See NOTE 2.)

Black Mark

Tag paper

Black Mark

White part

Black Mark Sensor

Press the [FEED] key

and [RESTART] key at

the same time.

NOTES:

1.

Make sure to adjust the black mark sensor using the white part of the tag paper as

a criterion. Though an adjustment can be performed with the black mark, it may

cause a paper jam error.

2.

Pressing the [PAUSE] key validates the sensor adjustment. The value of the

sensor is displayed up to 5.0 V.

3.

When the difference is less than 1.5 V, used media may be improper (unspecified),

or sensitivity may be dull due to an excessively old or dirty sensor. In this case

change the media to one specified, or replace or clean the sensor. Then re-adjust

the black mark sensor.

6.5 SENSOR SETTING MODE

6.5.2

Black Mark Sensor Adjustment

Black mark sensor setting should be performed after replacing the CPU PC board or changing the

tag paper to another maker’s, or when a paper feed error occurs. The black mark sensor has a

movable and a fixed mode. These are selected by the DIP switch.

After changing the black mark sensor type, follow the procedure below to make an adjustment.