WBPEEUI220772A0

4 - 1

Section 4

Troubleshooting

Introduction

This section provides some basic troubleshooting guidelines for

the Conductor VMS Series 43 Auxiliary Terminal. It is not

meant to be all inclusive. Be sure to have all the manufac-

turer’s documentation on non-Elsag Bailey Process Automa-

tion components accessible. Also refer to Table

for any

applicable Elsag Bailey documents. Many of those documents

also provide troubleshooting information. If problems exist

that are not included in any of the documentation, contact the

local Elsag Bailey service office for assistance.

This section contains a general troubleshooting table and a

troubleshooting sequence flowchart that directs troubleshoot-

ing personnel to the appropriate procedures.

NOTE: Put circuit boards containing MOS devices into antistatic bags when

stored or shipped back to the factory. Do not repair circuit boards in the field.

All repairs and adjustments should be performed by qualified personnel.

Troubleshooting

Table

is a general troubleshooting guide. If the general

troubleshooting guide does not eliminate the problem, refer to

Figure

and follow the troubleshooting sequence

.

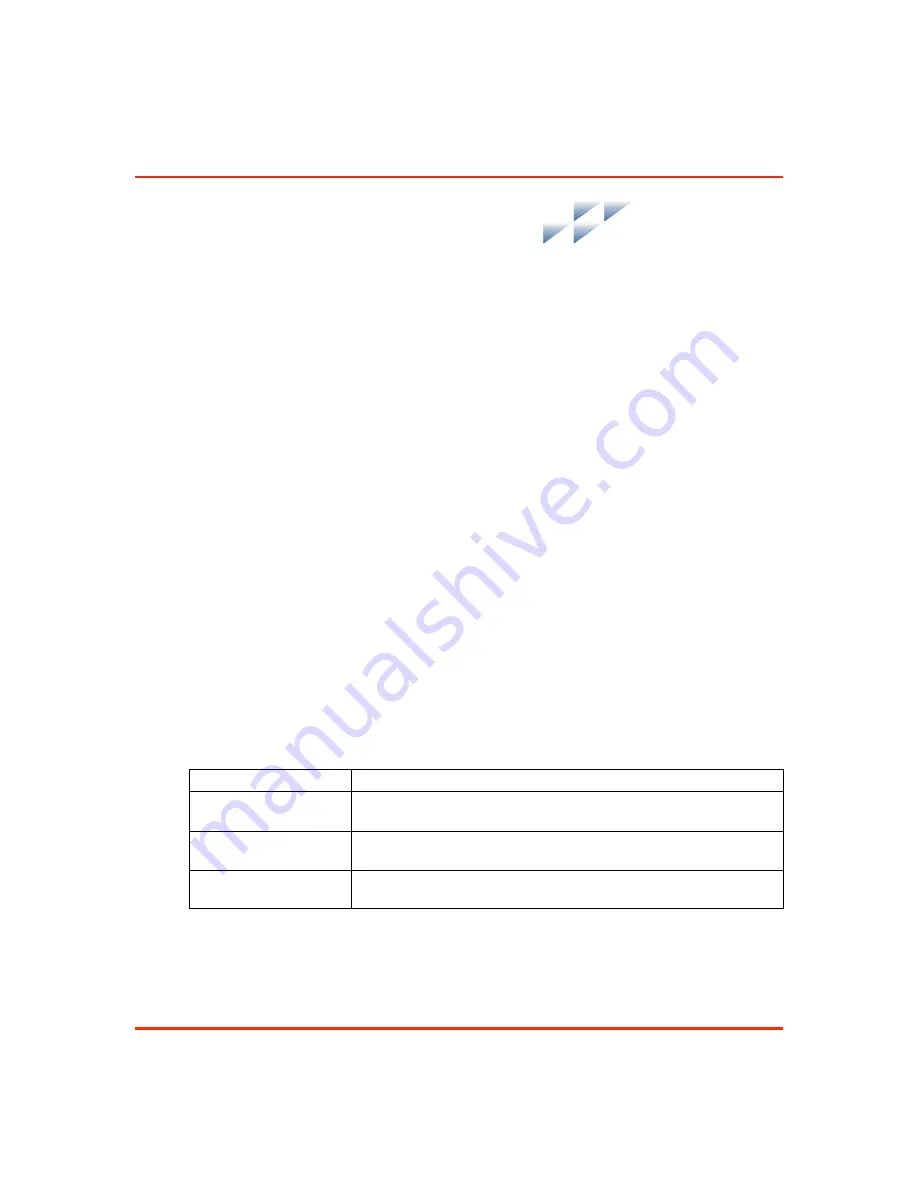

Table 4-1. Troubleshooting Guide

Symptom

Possible Problem or Solution

No power indicator on

circuit

No AC power at auxiliary terminal. Check AC wiring on input. Check AC

on PEP. Check breaker light on PEP.

Breaker off but indicator

on

Check breaker contacts. Check breaker wiring. Check AC input wiring.

Improper/ incomplete

start-up

Refer to the CPU

instruction shipped with the auxiliary terminal.

Summary of Contents for C-I-CV43C

Page 1: ...Bailey Hartmann Braun TM Instruction Conductor Conductor VMS Series 43 Auxiliary Terminal...

Page 13: ...WBPEEUI220772A0...

Page 23: ...WBPEEUI220772A0...

Page 37: ...WBPEEUI220772A0...

Page 47: ...WBPEEUI220772A0...

Page 49: ...WBPEEUI220772A0...

Page 57: ...WBPEEUI220772A0...

Page 61: ...WBPEEUI220772A0...

Page 75: ...WBPEEUI220772A0...

Page 87: ...PR6 4 WBPEEUI220772A0 Procedure Figure PR6 3 CPU Input Voltage T00440A REAR OF CPU 230 V 115 V...

Page 93: ...WBPEEUI220772A0...

Page 103: ...WBPEEUI220772A0...

Page 109: ...WBPEEUI220772A0...

Page 117: ...WBPEEUI220772A0...

Page 121: ...WBPEEUI220772A0...

Page 123: ...WBPEEUI220772A0...

Page 125: ...WBPEEUI220772A0...

Page 129: ...WBPEEUI220772A0...

Page 131: ...PR25 2 WBPEEUI220772A0 Procedure Figure PR25 1 Multibus Card Cage T01448A FRONT VIEW SCREWS 4...

Page 139: ...PR28 4 WBPEEUI220772A0 Procedure Figure PR28 2 PEP Replacement T01308A FRONT VIEW SCREWS 5...

Page 151: ...WBPEEUI220772A0...

Page 153: ...WBPEEUI220772A0...

Page 159: ...WBPEEUI220772A0...

Page 169: ...WBPEEUI220772A0...

Page 173: ...WBPEEUI220772A0...