Micro Weld Heads

CWS

−

D100

−

B Welding System

2005 Swagelok Company, All rights reserved

September 2005

4-10

3.

Insert the first work piece, butting the weld end against

the gage surface. Close and latch that side of the fixture.

Make sure that the latch is fully closed against the body

of the fixture. See Figure 4-13.

4.

Remove the centering gage.

5.

Open the other side of the fixture and insert the second

work piece. Butt the weld ends together. Close and latch

that side.

6.

Check the weld joint for proper fit and alignment. See

Figure 4-13. Verify that the latches are fully closed. See

Figure 4-13 (Series 4) or Figure 4-14 (Series 8).

7.

Connect the purge gas line to the work pieces. See

Figure 2-6 in Section 2,

Installation

.

8.

Open the shut-off valve in the purge gas line.

9.

Set the flow meters according to the weld procedure

guideline for both the shielding and internal purge gas.

Table 4-1

Shield Gas Flow Rates (Argon)

Weld Head Series

std ft

3

/h (L/min)

4MH

8 to 10 (4 to 4.7)

8MH

15 to 20 (7.1 to 9.4)

The length of time for internal purge before welding

depends on the internal volume and length of the work

piece to be welded. See Appendix G,

Gas Flow

Rate Tables

.

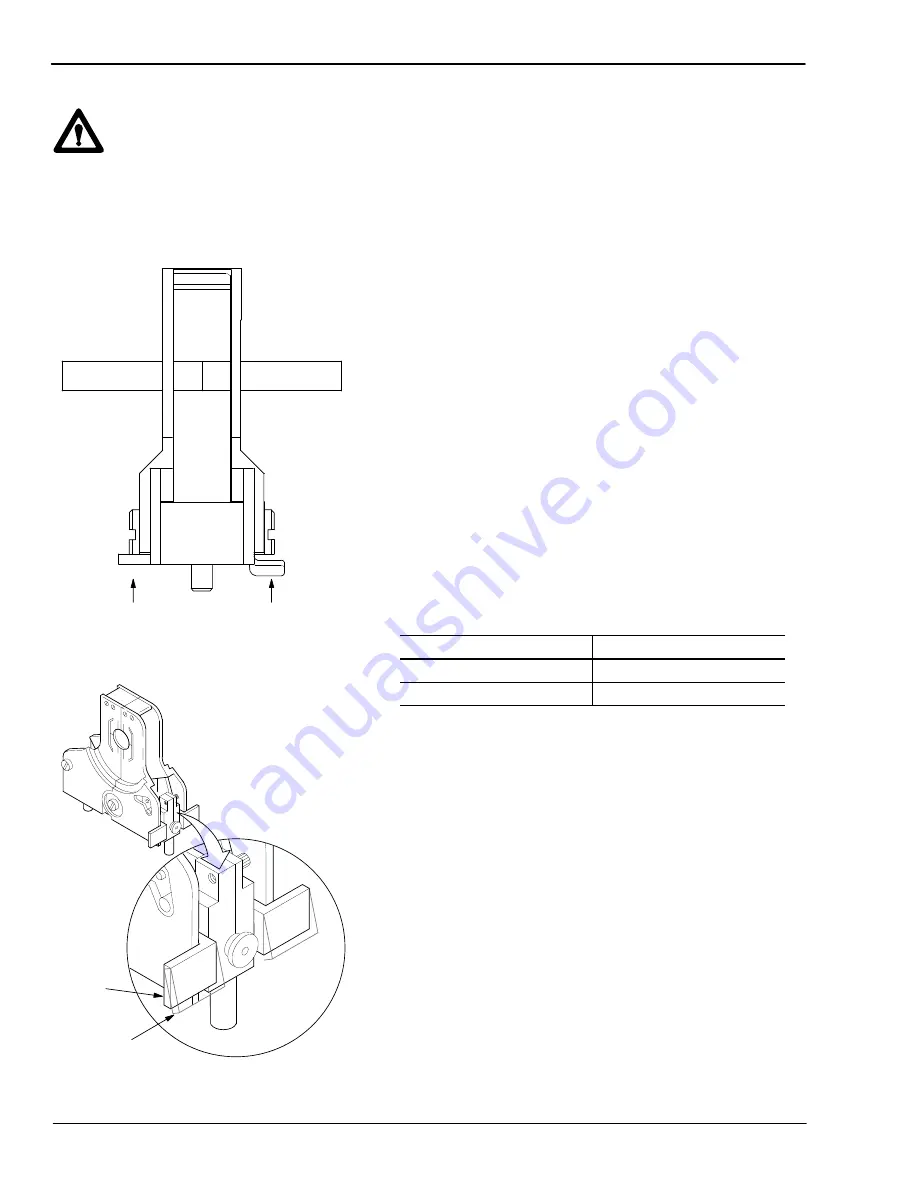

Caution!

When closing the fixture,

be sure the moving side

of the fixture engages

into the small groove on

the stationary side of

the fixture.

Figure 4-13 Checking the Weld Joint

(Series 4 Fixture)

Correct

Wrong

Figure 4-14 Proper Latch Position

(Series 8 Fixture)

Correct

Wrong