Operation

CWS

−

D100

−

B Welding System

2005 Swagelok Company, All rights reserved

September 2005

3-28

4.

Restore power to the SWS by turning the

circuit breaker on.

5.

Press

STOP/RESET

to return the rotor to the

home position and visually inspect the

rotor smooth rotation.

Preparing the Work

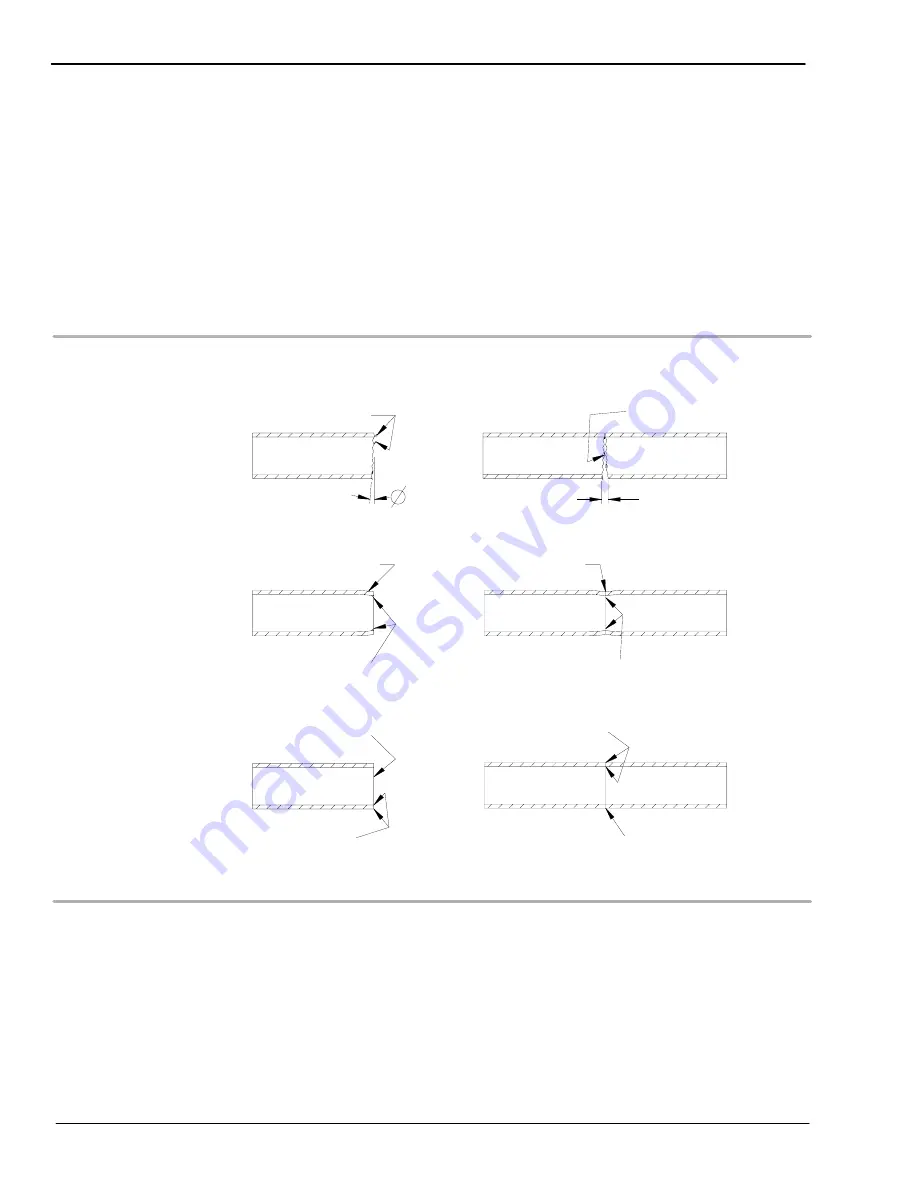

Refer to Figure 3-20. Prepare the tube pieces to be welded.

Figure 3-20 Tube Preparation

Method

Result

Hack Saw Cut

Burrs

Gap

Burrs in

Flow Path

Tube Cutter

End Roller in by Cutter

Burrs

Reduced Flow Area

Irregular Wall

Tube Facing Tool

Square Corners

Face Perpendicular

No Gaps

Smooth Transition

Blade and Roller

at Wall Faces

to Axis

Thickness

Tubing must be square and burr-free to ensure

repeatable, high-quality autogenous fusion welds. Cut

the tubing to length with a hacksaw or tube cutter. Face

the tube ends with a lathe or a portable facing tool.

Deburr the ends, making sure that both the inside and

outside diameters are square and burr-free. Clean the

tube ends using an appropriate solvent.