L3214 Laser Cutter

User’s Manual

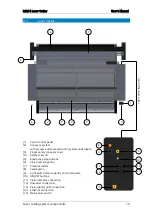

Laser cutting system components

18

2.1.2

Conveyor system

The conveyor system, equipped with blade planks, transports the material through the working

area and then out of the machine. The material is held down by the vacuum/extraction system

underneath the conveyor bed, resulting in a clean cut and precise material transport.

ATTTENTION

: Do not lean on the conveyor planks as this can cause deflection.

2.1.3

Finger safety conveyor cover

More information can be found in chapter 1.1.5.2

on page 11.

2.1.4

Safety cover lid

More information can be found in chapter 1.1.5.2

on page 11.

2.1.5

Emergency stop buttons

More information can be found in chapter 1.1.5.1

on page 10.

2.1.6

Vision camera gantry

The L3214 laser cutter is equipped with the Vision camera gantry. The Vision camera system

uses integrated cameras to scan marks, black outlines, or barcodes, fast and accurately. It is

also possible to scan, feed and cut at the same time. This camera system supports the following

advanced work methods:

•

Cut-to-Frame (also known as Fixed Size cutting)

•

Barcode workflow (requires Pro Pack)

•

Trace & Cut

•

Cut-on-the-Fly

More information on the advanced work methods can be found in the Go Produce Laser Edition

user manual.

2.1.7

Pressure rollers

There are two pressure rollers available: one on the front and one on the rear of the conveyor

bed. They should be placed in the lower recess to improve traction of the material on the

conveyor when cutting.

2.1.8

Feed button

When this button is pressed, the conveyor will immediately advance a preset distance (value

in mm). This distance can only be set in service mode.