36

Section 6

COMPRESSOR OPERATION

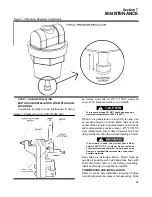

MINIMUM PRESSURE VALVE

PRESSURE RELIEF VALVE

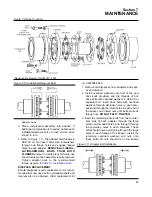

BLOWDOWN VALVE ASSEMBLY

THERMAL MIXING VALVE

FLUID STOP VALVE

SUMP SIGHT GLASSES

SEPARATOR RETURN LINE SIGHT GLASSES

WATER PRESSURE SWITCH

DRAIN VALVES

Maintains 40 psig (2.8 bar) in the receiver tank when the

compressor is running loaded. Also incorporates a check

valve, which prevents compressed air backflow from the sys-

tem when unloaded or shutdown.

Vents the sump vessel to atmosphere before the com-

pressed air pressure exceeds rated tank pressure. Its oper-

ation indicates fault with the Supervisor operation unload

pressure set too high or failure of solenoid valve #1.

Vents the sump vessel to atmosphere during unloading and

shutdown.

Bypasses fluid flow around the cooler until the fluid reaches

a temperature of 170°F, 77°C (195°F for water cooled KT and

≥

150 psi/ 10.3 bar). Useful for fast warm-up during start.

Maintains a minimum temperature during periods of low load

or low ambient temperatures.

Blocks the flow of fluid to the compressor during shutdown,

thus preventing the discharge of fluid through the compres-

sor inlet pipework.

Indicates level of lubricant in the sump. Located on the sump

side, fluid level should be maintained at a level between the

high and low sight glass.

Indicate fluid flow in the separator return lines. Large flow

should be visible during full load operation; little to no flow

during unloaded operation. Sluggish flow during full load

operation indicates the need to clean the strainers fitted to

the return lines.

De-energizes the starter, via the Supervisor, if the

water pressure falls below 10 psig (0.7 bar). This switch is not

adjustable. Used on water-cooled packages only.

Lubricant sump drain valve.

6.3 INITIAL START-UP PROCEDURE

The following procedure should be used to make

the initial start-up of the compressor.

1. Read the preceding pages of this manual thor-

oughly.

2. Jog motor to check for correct rotation of fan

(refer to Section 4.7).

3. Be sure that all preparations and checks

described in the Installation Section have been

made.

4. Open the shut-off valve to the service line.

5. Check for possible leaks in piping.

6. Slowly close the shut-off valve to assure proper

nameplate pressure unload setting is correct.

The compressor will unload at nameplate pres-

sure. If adjustments are necessary, see Control

System Adjustments.

7. Observe the operating temperature. If the oper-

ating temperature exceeds 200°F (93°C) [215°F

(102°C) for water-cooled 24KT and > 150 psi],

CONTROL OR INDICATOR (CONT.)

PURPOSE (CONT.)

Summary of Contents for LS-32

Page 6: ...NOTES...

Page 14: ...Section 2 DESCRIPTION 8 Figure 2 2 Compressor Piping and Instrument Diagram 02250140 998R02...

Page 16: ...Section 2 DESCRIPTION 10 Figure 2 2 Compressor Piping and Instrument Diagram 02250140 998R02...

Page 21: ...Section 2 DESCRIPTION 15 Figure 2 5A Control System KEY COMPONENTS...

Page 22: ...Section 2 DESCRIPTION 16 Figure 2 5B Control System START...

Page 23: ...Section 2 DESCRIPTION 17 Figure 2 5C Control System MODULATION...

Page 24: ...Section 2 DESCRIPTION 18 Figure 2 5D Control System UNLOAD...

Page 25: ...Section 2 DESCRIPTION 19 Figure 2 5E Control System FULL LOAD...

Page 28: ...Section 3 SPECIFICATIONS 22 Figure 3 2 Identification LS 32 Air cooled 02250140 997R01...

Page 32: ...Section 5 SUPERVISOR CONTROLLER 26 Figure 5 1 Supervisor Control Panel...

Page 44: ...38 NOTES...

Page 56: ...50 NOTES...

Page 59: ...53 NOTES...

Page 60: ...Section 8 ILLUSTRATIONS AND PARTS LIST 54 8 3 MOTOR COMPRESSOR FRAME AND PARTS 02250140 989R01...

Page 62: ...Section 8 ILLUSTRATIONS AND PARTS LIST 56 8 3 MOTOR COMPRESSOR FRAME AND PARTS 02250140 989R01...

Page 64: ...Section 8 ILLUSTRATIONS AND PARTS LIST 58 8 4 AIR INLET SYSTEM 02250140 990R02...

Page 66: ...Section 8 ILLUSTRATIONS AND PARTS LIST 60 8 4 AIR INLET SYSTEM 02250140 990R02...

Page 68: ...Section 8 ILLUSTRATIONS AND PARTS LIST 62 8 5 FLUID COOLING SYSTEM AIR COOLED 02250140 994R00...

Page 70: ...Section 8 ILLUSTRATIONS AND PARTS LIST 64 8 5 FLUID COOLING SYSTEM AIR COOLED 02250140 994R00...

Page 72: ...Section 8 ILLUSTRATIONS AND PARTS LIST 66 8 6 AIR PIPING SYSTEM AIR COOLED 02250140 992R01...

Page 74: ...Section 8 ILLUSTRATIONS AND PARTS LIST 68 8 6 AIR PIPING SYSTEM AIR COOLED 02250140 992R01...

Page 76: ...Section 8 ILLUSTRATIONS AND PARTS LIST 70 02250140 993R01 8 7 FLUID PIPING SYSTEM AIR COOLER...

Page 78: ...Section 8 ILLUSTRATIONS AND PARTS LIST 72 02250140 993R01 8 7 FLUID PIPING SYSTEM AIR COOLER...

Page 80: ...Section 8 ILLUSTRATIONS AND PARTS LIST 74 02250140 991R00 8 8 SUMP AND PARTS...

Page 82: ...Section 8 ILLUSTRATIONS AND PARTS LIST 76 02250140 991R00 8 8 SUMP AND PARTS...

Page 84: ...Section 8 ILLUSTRATIONS AND PARTS LIST 78 8 9 SULLICON CONTROL 02250134 158R00...

Page 86: ...Section 8 ILLUSTRATIONS AND PARTS LIST 80 8 10 COMPRESSOR ACTUATOR...

Page 88: ...Section 8 ILLUSTRATIONS AND PARTS LIST 82 8 11 PNEUMATIC CONTROLS 02250140 996R00...

Page 90: ...Section 8 ILLUSTRATIONS AND PARTS LIST 84 8 11 PNEUMATIC CONTROLS 02250140 996R00...

Page 92: ...Section 8 ILLUSTRATIONS AND PARTS LIST 86 8 11 PNEUMATIC CONTROLS 02250140 996R00...

Page 94: ...Section 8 ILLUSTRATIONS AND PARTS LIST 88 8 12 CONTROL BOX SOLID STATE 02250122 005R04...

Page 96: ...Section 8 ILLUSTRATIONS AND PARTS LIST 90 8 13 CONTROL BOX FULL VOLTAGE 02250122 511R04...

Page 98: ...Section 8 ILLUSTRATIONS AND PARTS LIST 92 8 14 CONTROL BOX WYE DELTA 02250122 516R08...

Page 100: ...Section 8 ILLUSTRATIONS AND PARTS LIST 94 8 15 ENCLOSURE AIR COOLED 02250140 995R00...

Page 102: ...Section 8 ILLUSTRATIONS AND PARTS LIST 96 8 15 ENCLOSURE AIR COOLED 02250140 995R00...

Page 104: ...Section 8 ILLUSTRATIONS AND PARTS LIST 98 8 16 DECAL GROUP...

Page 106: ...Section 8 ILLUSTRATIONS AND PARTS LIST 100 8 16 DECAL GROUP...

Page 108: ...Section 8 ILLUSTRATIONS AND PARTS LIST 102 8 16 DECAL GROUP...

Page 110: ...Section 8 ILLUSTRATIONS AND PARTS LIST 104 8 17 DECAL LOCATIONS...

Page 112: ...Section 8 ILLUSTRATIONS AND PARTS LIST 106 8 18 DECAL LOCATIONS ENCLOSURE...

Page 114: ...Section 8 ILLUSTRATIONS AND PARTS LIST 108 8 19 DECAL LOCATIONS CONTROL BOX...

Page 117: ...111 NOTES...