Global 400 User Manual

38 of 85

v1.1 revision 1

Chapter 3: Configuring the unit

2 February 2016

This setting controls the IP address of the qualifier for Ethernet networks.

Subnet Mask

Default: 255.255.255.0

This setting controls the subnet mask for Ethernet networks.

Gateway

Default: 192.168.1.113

This setting controls the default gateway setting for Ethernet networks.

Use DHCP

Default: No

This setting determines if the qualifier will attempt to automatically acquire a network address or

if it will use the one entered manually. When set to yes, the IP Address, Subnet Mask, and

Gateway settings are ignored.

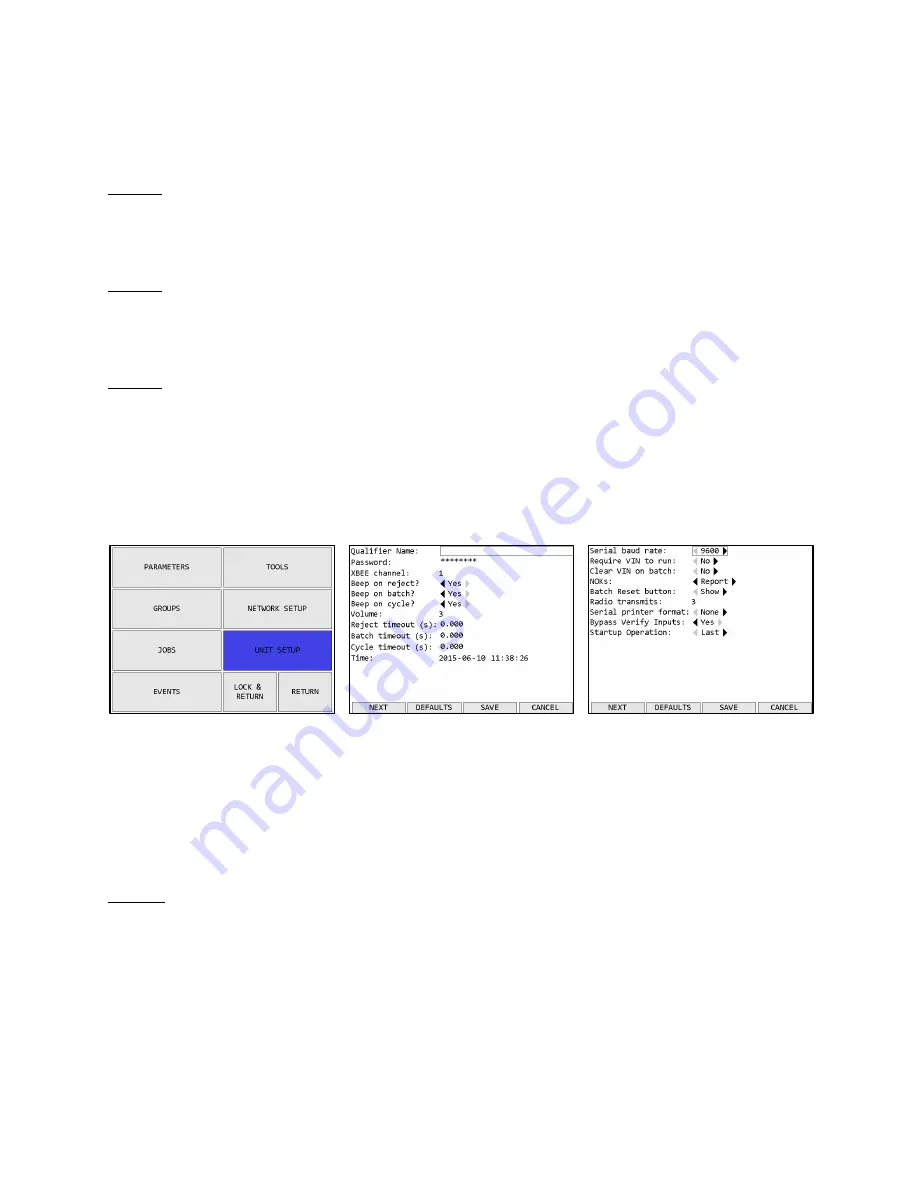

Unit Setup

The Unit Setup screen contains the settings for the overall unit.

Figure 40: Main menu – Unit Setup

Figure 41: Unit Setup screen – page 1

Figure 42: Unit Setup screen – page 2

Function keys

1.

NEXT – Goes to the other page of the unit setup screen.

2.

DEFAULTS – Goes to the Reset Defaults screen

3.

SAVE – Saves changes made to the qualifier configuration.

4.

CANCEL [ESC] – Cancels changes made to the qualifier configuration.

Page 1

Qualifier Name

The qualifier name can be up to 25 numbers, letters, or decimal points.

The qualifier name is sent to the network in the Controller Name field of various commands.