Replace hose lines if they display the following

abnormalities:

●

Outer layer has been damaged, or is brittle

or cracked

●

Leaking

●

Deformation (e.g. with blisters or kinks)

●

A fitting has come loose

●

A fitting is badly damaged or corroded

Replace pipes if they display the following ab-

normalities:

●

Abrasion

●

Deformation and bending

●

Leaking

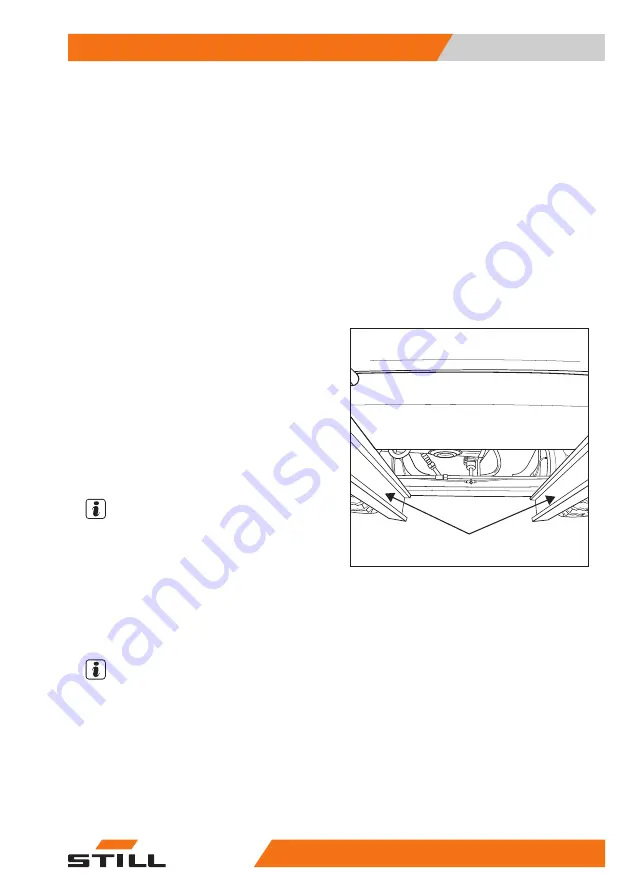

Lubricating the lift mast and roll-

er track

–

Remove dirt and lubricant residue from the

roller track.

–

Lubricate the roller tracks (1) of the outside,

middle, and inside mast with a super-pres-

sure adhesion lubricant to reduce wear.

See

⇒

Chapter "Maintenance data table",

NOTE

Spray the roller track evenly from a distance of

approx. 15-20 cm. Wait approx. 15 minutes

until the equipment is ready to use again.

Greasing the automatic tow cou-

pling

NOTE

Wear to moving parts can be significantly re-

duced by appropriate servicing and regular lu-

brication of the coupling.

–

Avoid over-greasing!

1

6210_800-020

Maintenance

5

Preserving operational readiness

365

56358042501 EN - - 11

Summary of Contents for RX60-60

Page 2: ......

Page 13: ...1 Foreword ...

Page 20: ...Overview Foreword 1 Your truck 8 56358042501 EN 11 ...

Page 41: ...2 Safety ...

Page 70: ...Safety 2 Emissions 58 56358042501 EN 11 ...

Page 71: ...3 Overviews ...

Page 83: ...4 Operating ...

Page 336: ...Operating 4 Decommissioning 324 56358042501 EN 11 ...

Page 337: ...5 Maintenance ...

Page 344: ...Maintenance 5 General maintenance information 332 56358042501 EN 11 ...

Page 381: ...6 1000 hour maintenance annual mainte nance ...

Page 385: ...7 Technical data ...

Page 398: ...Technical data 7 Fuse assignment 386 56358042501 EN 11 ...

Page 407: ......

Page 408: ...STILL GmbH 56358042501 EN 11 ...