– 19 –

THEORY OF OPERATION

3.4 Photographics & ROS

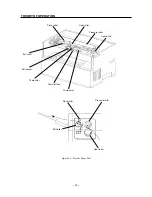

• HVPS (HVPS: High Voltage Power Supply)

The HVPS supplies voltage/current to the BCR, magnetic roller, BTR and drum during the charging, developing and

transfer steps. It also supplies current to the fan. (The front cover interlock switch is mounted onto the HVPS.)

• ROS Assembly (ROS: Raster Output Scanner)

The ROS assembly consists of the LD assembly, the scanner assembly, the SOS PWB and the mirror. Parts in the ROS

assembly are referred to as ROS items.

LD Assembly (LD: Laser Diode)

The LD assembly converts electrical signals into a laser beam and emits light.

The laser diode output (LD power) is kept constant and transmitted through the monitor’s circuits.

Scanner Assembly

A polygonal mirror with four specular surfaces is mounted on the scanner motor which rotates at a constant speed.

The rotation of the polygonal mirror changes the laser beam’s angle of reflection and causes one surface of the

mirror to scan one line (in the direction of the drum’s axis).

The laser beam reflected by the polygonal mirror is irradiated onto the drum’s surface via the lens and mirror.

SOS PWB (SOS: Start of Scan)

The irradiation of the laser beam onto the SOS sensor causes the laser beam to be converted into an electrical signal

(SOS signal) and allows the initial scanning position of a line to be detected.

• CRU Sensor PWB (CRU: Customer Replaceable Unit)

The CRU sensor consists of a CRU switch which detects the presence of the EP toner cartridge and is turned ON or

OFF in response to the CRU actuator. The CRU switch is in series with the circuit emitting the laser beam and ensures

the safety of the laser beam.

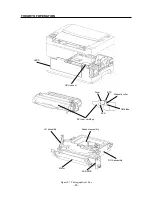

• EP toner cartridge (EP: Electrical Photographics)

The EP toner cartridge consists of the drum, BCR, magnetic roller, CM blade and cleaning blade.

Drum

The drum is constructed of an aluminum cylinder covered with an OPC (organic photo conductor) sensitive material with

photoconductive properties (the ability to retain the electric charge in darkness and set the charge to neutral in light). The drum

produces a printed image based on the potential difference (latent electrostatic image) on its surface.

BCR (BCR: Bias Charge Roller)

The BCR sets the drum’s surface to a uniform electrical charge.

Magnetic Roller

The magnetic roller supplies toner to the drum for developing a latent electrostatic image on the surface of the drum.

BTR (BTR: Bias Transfer Roller)

The BTR applies a positive charge to the back of the paper and transfers the toner from the drum’s surface to the paper.

CM Blade (CM: Charge Metal)

The CM blade not only uniformly controls the amount of toner on the surface of the magnetic roller, but also uses friction to

give the toner its electric charge.

Cleaning Blade

The cleaning blade cleans the surface of the drum by scratching off the residual toner after the transfer step.

Summary of Contents for WinType 4000

Page 1: ...WinType 4000 TECHNICAL MANUAL SECOND EDITION LASER PRINTER ...

Page 4: ......

Page 6: ... 2 GENERAL SPECIFICATIONS ...

Page 14: ... 10 THEORY OF OPERATION ...

Page 26: ... 22 THEORY OF OPERATION Figure 2 9 Electrical ...

Page 28: ... 24 REPLACEMENT AND ADJUSTMENT OF PARTS ...

Page 62: ... 58 REPLACEMENT AND ADJUSTMENT OF PARTS ...

Page 64: ... 60 MAINTENANCE GUIDE ...

Page 114: ... 110 MAINTENANCE GUIDE ...

Page 116: ... 112 TROUBLESHOOTING ...

Page 176: ... 172 5 ELECTRICAL 5 1 Disassembly Drawing 1 2 3 4 14 4 14 2 14 1 14 3 13 12 11 6 5 7 8 9 10 ...

Page 179: ......