– 12 –

THEORY OF OPERATION

• Description of the Printing Process

Step

Details

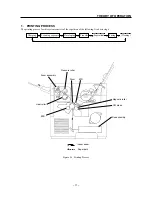

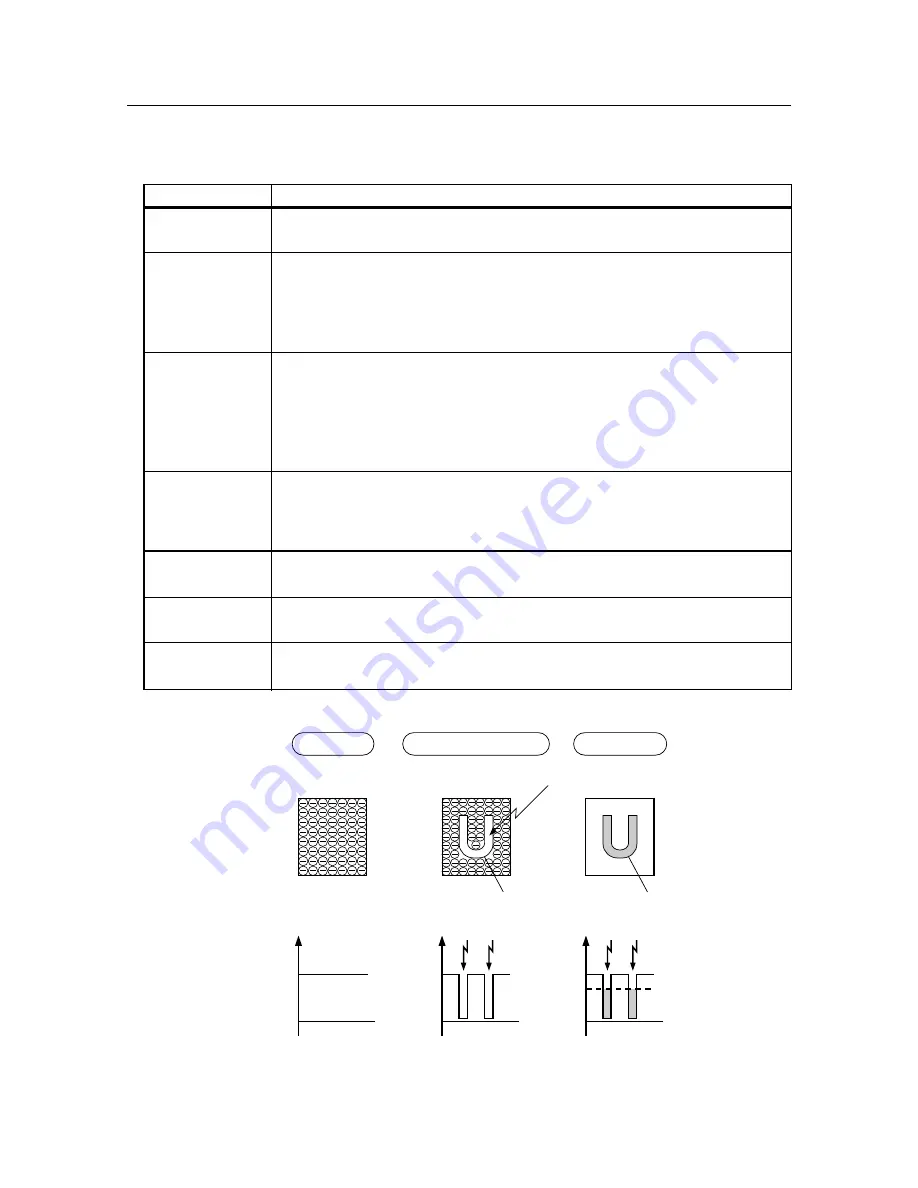

Charging

The surface of the rotating drum in the EP toner cartridge is uniformly negatively charged

by the electric charge from the BCR (Bias Charge Roller).

The ROS assembly scans the exposure by converting the image signal from the MCU PWB

into an optical signal (laser beam) and directs the laser beam onto the drum.

Scanning Exposure

When an image is present, a laser is emitted and the laser beam is irradiated onto the surface

of the drum causing the irradiated area to be set to a neutral charge, thus enabling an

invisible latent electrostatic image to be formed on the drum’s surface.

The latent electrostatic image on the drum’s surface attracts toner from the surface of the

magnetic roller in the EP toner cartridge, forming a visible image on the surface of the drum.

Developing

The magnet inside the magnetic roller causes the toner, which also has magnetic properties,

to adhere to the roller while the friction between the rotating magnetic roller and the CM

blade (Charge Metal Blade) negatively charges the toner, so that a thin layer of toner is n

the surface of the magnetic roller.

Transfer

A positive charge is applied to the back of the paper by the BTR (Bias Transfer Roller)

causing the toner on the drum’s surface to be transferred to the paper.

Applying a positive charge to the back of the paper causes the paper itself to be positively

charged, so that the paper adheres to the drum

(Separation)

The firmness of the paper causes the paper with the toner affixed to it to be separated from

the drum.

Fusing

The heat from the heat roller heated by the heat rod and the pressure from the pressure roller

causes the toner to be fused to the paper in the fuser assembly.

(Cleaning)

Any residual toner remaining on the drum after the transfer step is scraped off by the

cleaning blade which is in contact with the drum’s surface.

–350V

0

–V

–350V

0

–V

–350V

0

–V

–210V

(Developing bias)

Laser beam

Scanning Exposure

Developing

Charging

Toner image

(Visible image)

Electrostatic latent

image (Invisible image)

Drum’s surface

Voltage

Figure 2-2 Printing Process (Drum’s Surface)

Summary of Contents for WinType 4000

Page 1: ...WinType 4000 TECHNICAL MANUAL SECOND EDITION LASER PRINTER ...

Page 4: ......

Page 6: ... 2 GENERAL SPECIFICATIONS ...

Page 14: ... 10 THEORY OF OPERATION ...

Page 26: ... 22 THEORY OF OPERATION Figure 2 9 Electrical ...

Page 28: ... 24 REPLACEMENT AND ADJUSTMENT OF PARTS ...

Page 62: ... 58 REPLACEMENT AND ADJUSTMENT OF PARTS ...

Page 64: ... 60 MAINTENANCE GUIDE ...

Page 114: ... 110 MAINTENANCE GUIDE ...

Page 116: ... 112 TROUBLESHOOTING ...

Page 176: ... 172 5 ELECTRICAL 5 1 Disassembly Drawing 1 2 3 4 14 4 14 2 14 1 14 3 13 12 11 6 5 7 8 9 10 ...

Page 179: ......