9-13

Condition

Check contents

Remedy, other items

D) Overuns the limit.

1. Is the motor brake normal?

(Is it in a released condition?)

Refer to “Outline of Operating

the Manual Handle.”

2. Does the upper limit (or lower limit) switch

operate correctly? (Does it run idle?)

Adjust the limit switch.

E) The indication of

the hoisting distance

suddenly

changes

during operation.

(Or it displays the

same value: “00” or

“7F” mid way)

1. Is the rotary switch set correctly?

F) The display of the

hoisting distance does

not change.

1. Is the magnet at the top of the feed screw

correctly installed?

2. Is the clearance between the magnet at the

top of the feed screw and the reed switch too

wide?

(3) Refer to sensor adjustment.

(3) Sensor Adjustment

The sensor is adjusted prior to shipment from the factory. If further adjustment is necessary, carry it out as

follows.

3-1) Hoist Limit Switches (Model: HL-5000: One upper and lower limit switch)

1. Operation

These switches control the hoist motor. When the Up/Down pipe is ascending, the upper limit switch

operates, causing the hoist to stop. Likewise, when the Up/Down pipe is descending, the lower limit

switch operates, causing the hoist to stop.

2. Mounting position

One upper and lower switch on the side of the column

3. Adjustment method

By changing the position of the tap on the mounting plate of the limit switch, the upper limit mounting

position can be changed by up to 20 mm, and the lower limit mounting position by up to 40 mm (the

pitch is 20 mm).

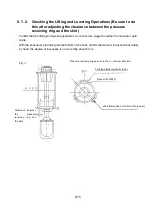

3-2) Hoisting Distance Detection Reed Switches (Model: GLS-S1: two)

1. Operation

The magnet mounted on the hoisting feed screw causes the reed switch to go ON/OFF for each

rotation. The resulting pulses are measured, and the number of rotations of the speed of the feed

screw is calculated, enabling the hoisting distance to be calculated. Because two reed switches are

used, the direction of rotation (in other words, whether the hoist is ascending or descending) is

detected.

2. Mounting position

Upper part of rear of column

3. Adjustment method

Basically, there is almost no need to carry out adjustment. However, if adjustment becomes

necessary, it is possible to adjust the distance from the magnet of the feed screw by inserting

washers, or the like, between the mounting fitting and also between the fitting and the column.

Summary of Contents for KCS-5200

Page 1: ...Model KCS 5200 Color Scanning Sonar Operation Manual Ver 1 48 E Rev 0...

Page 2: ......

Page 14: ......

Page 22: ...2 4...

Page 28: ...3 6...

Page 50: ...5 16...

Page 78: ...6 28 Menu Screen Sub Screen Orthogonal Display Axis...

Page 80: ...6 30...

Page 84: ...7 4...

Page 90: ...8 6...

Page 106: ...9 16...

Page 116: ...10 10...