77/238

Building Technologies

Modular Heating Controller RMH760B

CE1P3133en

HVAC Products

6 Boiler temperature control

05.02.2007

The proportional band has an impact on the controller’s P-characteristic.

With a setpoint / actual value deviation of 20 K, a setting of Xp = 20 K produces a

manipulated variable corresponding to the damper actuator’s running time.

The integral action time has an impact on the controller’s I-characteristic.

The derivative action time has an impact on the controller’s D-characteristic. If Tv = 0,

the controller has PI characteristics.

The majority of plants change their behavior depending on the load.

If the setting values are not adequately adjusted, the control system’s response is

either too slow or too fast. If the control system operates correctly in the upper load

range and not satisfactorily in the lower load range (or vice versa), average values must

be used, which may lead to a slightly less satisfactory control performance in the load

range which previously showed good performance.

It should be made certain that, when commissioning the modulating burner for the first

time, the default parameters for Xp, Tn and Tv will be used. To optimize and check the

control parameters, it is recommended to follow the procedure detailed below under

”Checking the control function”.

To check the behavior of the control system with the preset control parameters, the

following procedure is recommended:

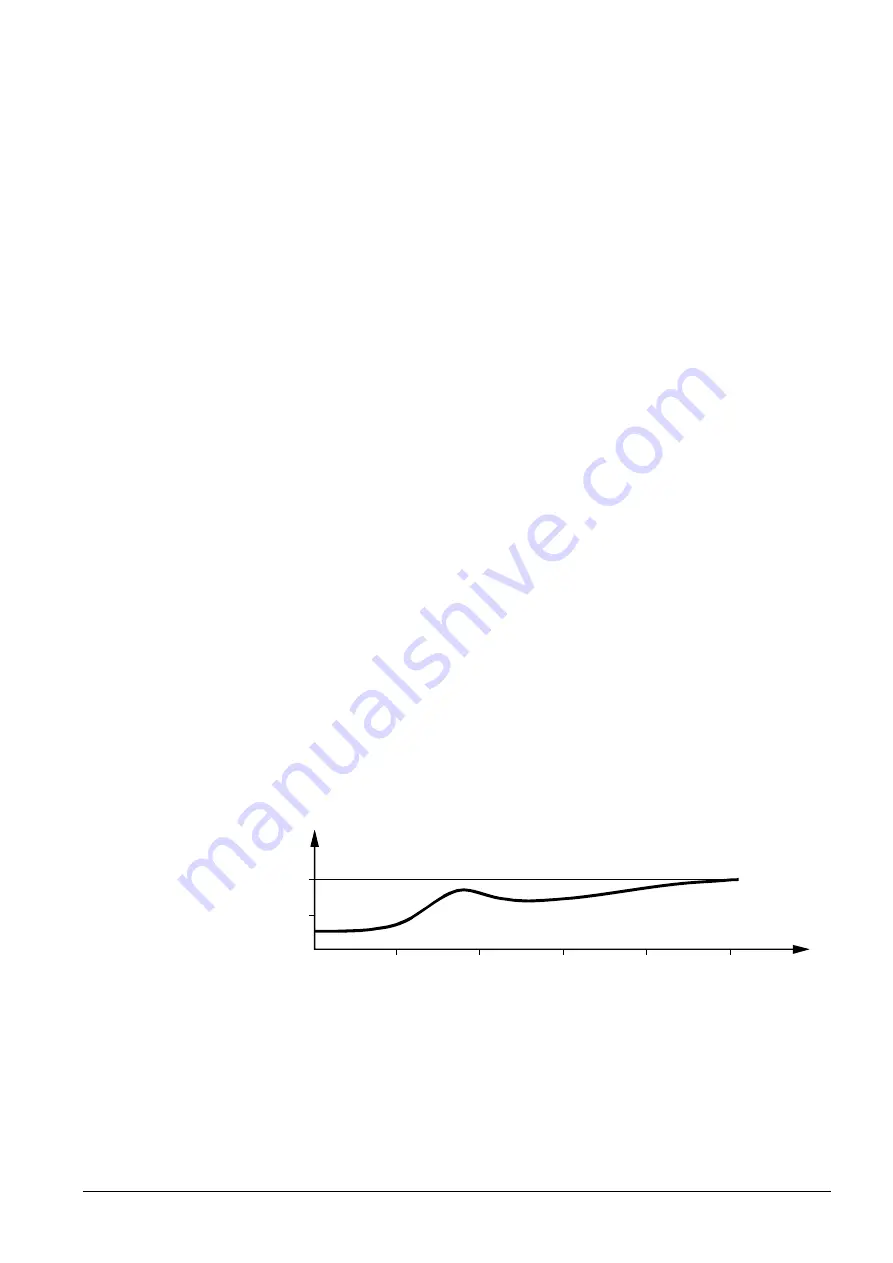

After the controller has reached and held the setpoint for a certain period of time,

change the setpoint by 5 to 10 %, either up or down. When making this test, it is of

advantage to have the plant operating in the lower load range where, usually, control is

more difficult.

In principle, control must be stable, but it can be fast- or slow-acting.

If fast control is required, the boiler temperature must reach the new setpoint fairly

quickly.

If fast control of a setpoint change is not a mandatory requirement, the control action

can be rather slow. This offers practically non-oscillating control, which reduces wear

on the actuator and on other electromechanical controls used in the plant.

If the correcting action does not produce the required result, the control parameters

should be adjusted as follows:

If the control system’s response is too slow, setting parameters Xp, Tv and Tn must be

decreased in steps. A new readjustment should be made only after the control action

resulting from the previous readjustment is completed.

t

TBo

TBoSetpt

31

32

D

10

1. Reduce Xp in steps of about 25 % of the previous value.

2. Reduce Tv in steps of 1 to 2 seconds (when the value of 0 is reached, the control-

ler operates as a PI controller).

If this is not sufficient:

3. Decrease Tn in steps of 10 to 20 seconds.

Proportional band (Xp)

Integral action time (Tn)

Derivative action time

(Tv)

Setting rules for

Xp, Tn and Tv

Checking the control

function

Control action is

too slow