161/238

Building Technologies

Modular Heating Controller RMH760B

CE1P3133en

HVAC Products

10 DHW heating

05.02.2007

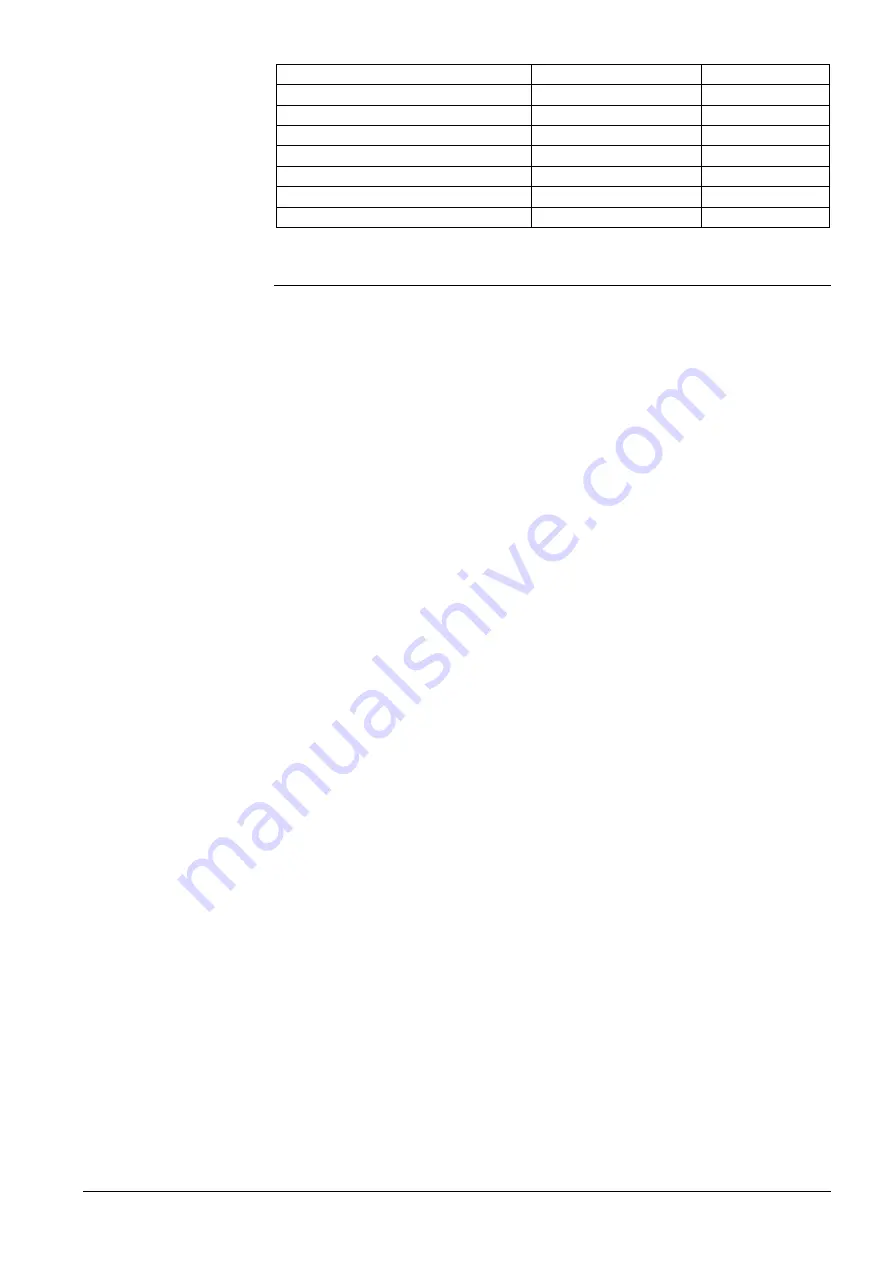

Operating line

Range

Factory setting

Actuator running time closing

1…600 s

15 s

P-band Xp at min load

1…200 K

100 K

P-band Xp at max load

1…200 K

33 K

Integr action time Tn at min load

0…600 s

30 s

Integr act time Tn at max load

0…600 s

6 s

Deriv act time Tv at min load

0…255 s

8 s

Deriv act time Tv at max load

0…255 s

2 s

10.5.1 Adapting the control parameters

Among other things, the characteristics of the controlled system are affected by the

current DHW consumption and the connection conditions on the primary side.

For the different types of plant, the connection conditions on the primary side can

change depending on the time of year.

In the winter, the primary line operates at 6 bar and 120 °C, but in the summer only at

2 bar and 90 °C. This means:

In order to convey constant amounts of energy, the primary valve’s stroke in the sum-

mer must be different from that in the winter.

The controller acquires these changes and constantly adjusts the control action.

The velocity of flow on the secondary side has a great impact on the control character-

istics. Since this shall not lead to any disadvantages for the user in the case of direct

DHW heating, additional setting choices have been made available. These are the

following setting parameters:

•

The P-band for the minimum load

•

The integral action time for the minimum load

•

The derivative action time for the minimum load

•

The P-band for the maximum load

•

The integral action time for the maximum load

•

The derivative action time for the maximum load

This means that changing connection conditions need not be considered since the

controller makes automatic readjustments.

For DHW control, the actuator running time must be set. When using asymmetric

actuators, the actuator running times for opening and closing can be individually set. In

the case of symmetric actuators, the actuator running times to be entered for opening

and closing are the same.

It is important to also set the actuator running times when using DC 0…10 V actuators.

Only these settings ensure correct functioning of the control system.

The proportional band influences the controller’s proportional behavior.

With a setpoint / actual value deviation of 20 K, a setting of Xp = 20 produces a ma-

nipulated variable corresponding to the actuator’s running time.

The integral action time influences the controller’s integral behavior.

The derivative action time influences the controllers D-behavior. If the integral action

time is set to 0, the controller produces no PI behavior.

The plant’s behavior changes depending on the load. To ensure that the control system

will produce satisfactory results both in the upper and lower load range, different values

Connection conditions

Example

Giving consideration

to the load

Actuator running time

Note

Proportional band (Xp)

Integral action time Tn

Derivative action time Tv

Setting rules for Xp, Tn

and Tv