9.1.2

Measuring the insulation resistance during the course of maintenance work

Measuring the insulation resistance and polarization index (PI) provides information on the

condition of the machine. It is therefore important to check the insulation resistance and the

polarization index at the following times:

● Before starting up a machine for the first time

● After an extended period in storage or downtime

● Within the scope of maintenance work

The following information is provided regarding the state of the winding insulation:

● Is the winding head insulation conductively contaminated?

● Has the winding insulation absorbed moisture?

As such, you can determine whether the machine needs commissioning or any necessary

measures such as cleaning and/or drying the winding:

● Can the machine be put into operation?

● Must the windings be cleaned or dried?

Detailed information on testing and the limit values can be found here:

"Testing the insulation resistance and polarization index" (Page 55)

9.1.3

Inspections in the event of faults

Natural disasters or unusual operating conditions, such as overloading or short circuit, are

faults that overload the machine electrically or mechanically.

Immediately perform an inspection after such faults.

9.1.4

First service after installation or repair

Perform the following checks after approximately 500 operating hours or at the latest six

months after commissioning:

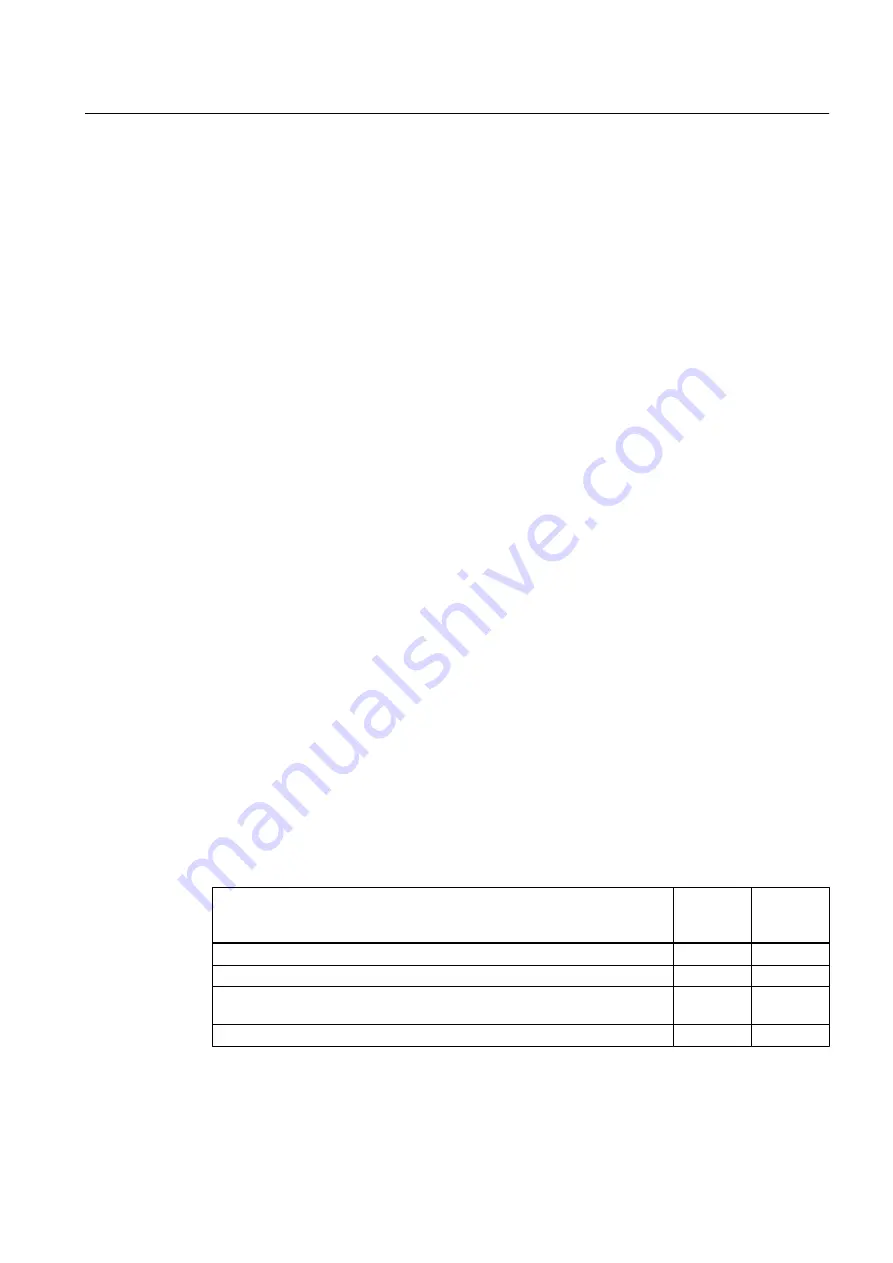

Table 9-1

Checks after assembly or repair

Check

When the

motor is

running

At stand‐

still

The stated electrical characteristics are being observed.

X

The permissible bearing temperatures are not exceeded (Page 101).

X

The smooth running characteristics and machine running noise have not

deteriorated.

X

The motor foundation has no cracks and indentations. (*)

X

X

(*) You can perform these checks while the motor is running or at a standstill.

Maintenance

9.1 Inspection and maintenance

SIMOTICS FD 1LH1

Operating Instructions 01/2019

125

Summary of Contents for SIMOTICS FD 1LH1

Page 2: ...23 01 2019 19 26 V11 01 ...

Page 28: ...Description SIMOTICS FD 1LH1 28 Operating Instructions 01 2019 ...

Page 122: ...Operation 8 10 faults SIMOTICS FD 1LH1 122 Operating Instructions 01 2019 ...

Page 140: ...Maintenance 9 2 Corrective Maintenance SIMOTICS FD 1LH1 140 Operating Instructions 01 2019 ...

Page 162: ...Disposal 11 5 Disposal of components SIMOTICS FD 1LH1 162 Operating Instructions 01 2019 ...

Page 164: ...Service and Support SIMOTICS FD 1LH1 164 Operating Instructions 01 2019 ...

Page 168: ...Quality documents SIMOTICS FD 1LH1 168 Operating Instructions 01 2019 ...

Page 173: ......